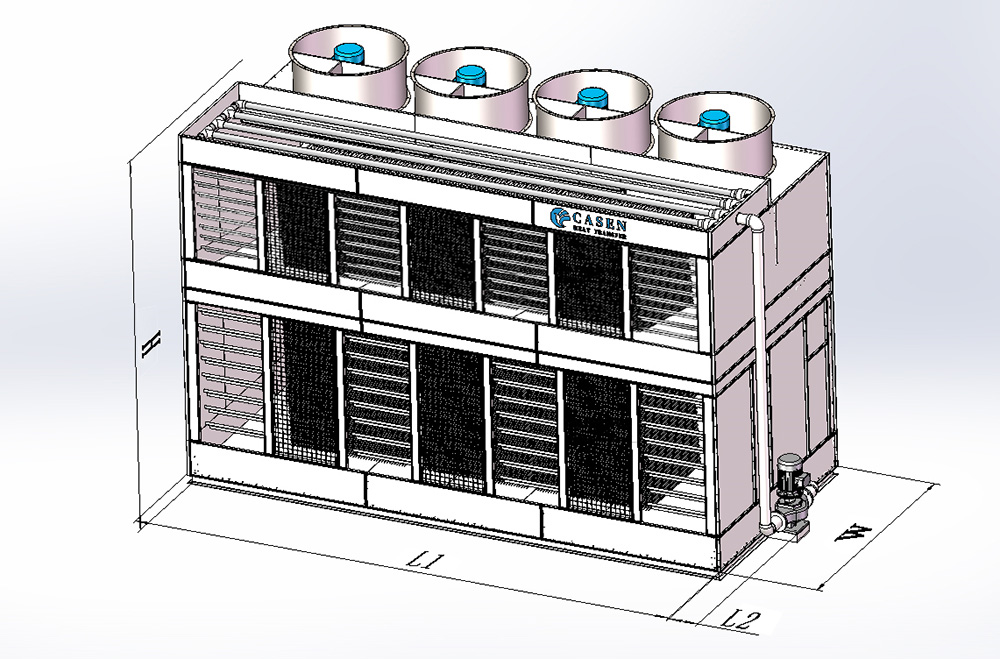

KEH- HORIZONTAL FLOW TYPE EVAPORATIVE CONDENSER

KEH evaporative condenser is a horizontal flow type evaporative condenser with PVC fill above the heat exchange coil. It is suitable for large industrial refrigeration projects.

In the process of circulation, the spray water reduces the water temperature through the PVC heat sink (filler), forming a feng shui flow in the same direction with the fresh incoming air. The coil mainly relies on the spray water for heat exchange. The lower the spray water, the better the cooling effect. An important feature of such an operating principle is the maximum possible suppression of the coil volume. Thus, reducing costs.

Key Benefit

100% heat rejection guarantee

Reliable

With fill cooling, cost effective

Large maintenance space

KEH Characteristics

Horizontal Flow, Axial Fan, Induced Draft

CTI Standard STD-201(21) Coil Design

Capacity Range100 - 3000KW(For Single cell models, nominal R717 KW,suitable to container delivery)

Typical Applications

Installation require a single air inlet

Indoor installations

Suitable for large projects

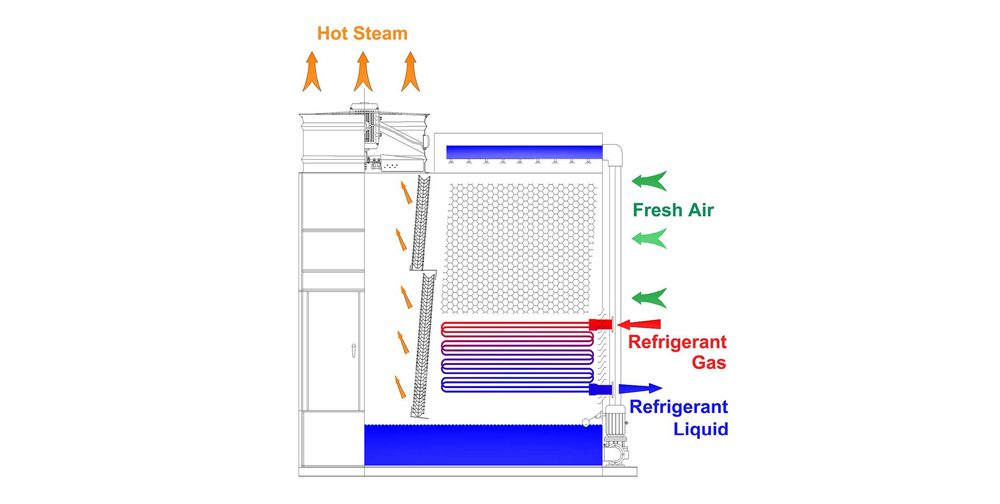

PRINCIPLE OF OPERATION

The hot refrigerant gas enters the condenser coil at the bottom of the unit. Cooled water from the unit basin is pumped and sprayed over the condenser coils, and ambient air is simultaneously drawn into the unit from both side of fill and coil, that is cross flow to the spraying water. With less wind resistance, the heat rejection can be increased significantly. KEH condensing process is similar to KEF type.

PRODUCT DESIGN FEATURES

1.Excellent heat exchanging performance with the same direction of wind and water

2.The KEH series utilizes a combination of air-water mixed-flow secondary heat exchange coils and PVC packing to achieve highly efficient heat exchange performance. At the same time, it effectively reduces the formation of scale on the pipe wall.

3.Air and spray water flow through the coil at the same time, so that the spray water can cover the coil surface to the maximum extent to ensure that the coil surface is completely wet. Compared to counterflow towers, the formation of scale on the coil wall is greatly reduced.

4.High-efficiency heat exchanger (multiple types and materials available)

1.Packing design, suppresses coil volume, reduces costs

The packing design greatly improves the efficiency of shower heat transfer, and reduces the air volume requirement for more energy saving. Spray water in the process of circulation through the PVC heat sink (packing) to reduce the water temperature, and fresh air into the formation of air and water flow in the same direction, the coil mainly rely on the spray water for heat transfer, the lower the spray water the better the cooling effect. The lower the spray water, the better the cooling effect. The important feature of this operation principle is to maximize the possible suppression of the coil volume, thus reducing the cost.

2.Extra large access space

The large access space, access doors, and passageways provide a spacious interior where inspectors can easily perform a variety of maintenance tasks, making maintenance more convenient.

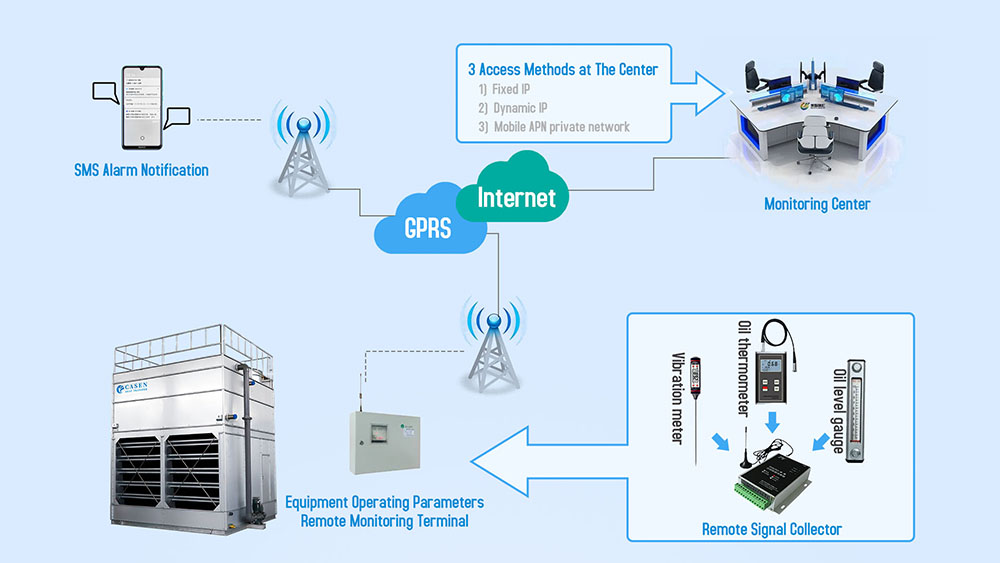

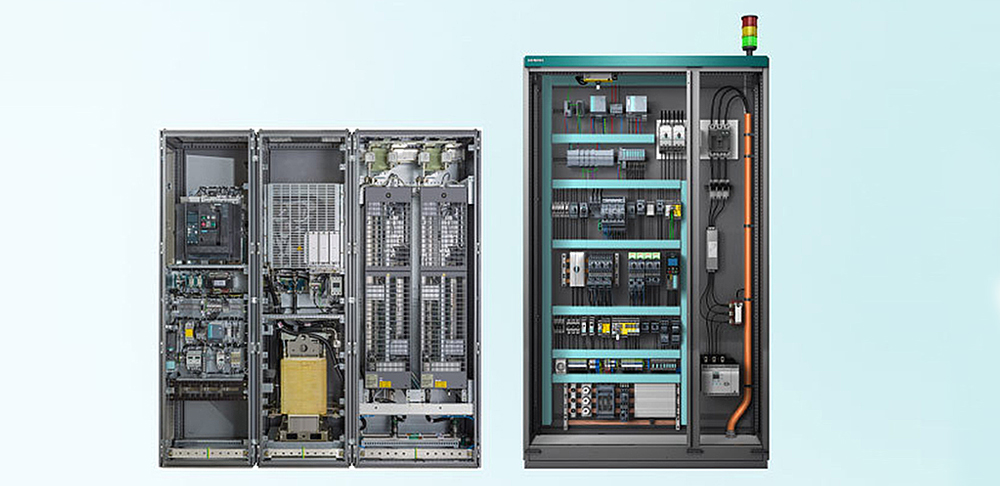

3.Automatic control

PLC intelligent control unit, automatic adjustment, intelligent alarm.

Customized control cabinets are available for greater convenience and intelligence, identifying temperature signals to start or shut down the corresponding motors/fans for economical operation and energy savings.

Anti-freeze design

Low noise design

Coils are available in a variety of materials - hot-dip galvanized carbon steel pipe/stainless steel pipe/purple copper pipe

Fan: frequency conversion/non-frequency conversion control; air blower, blades of various materials can be selected