Executive summary

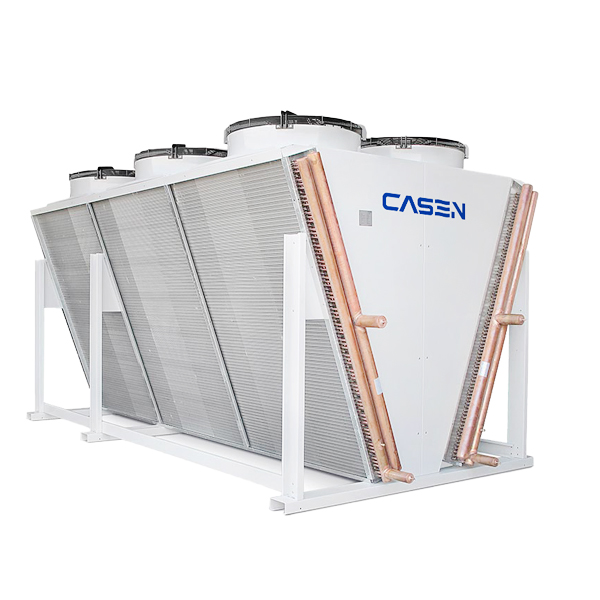

One Casen closed-circuit cooling tower has passed final factory tests and been loaded onto a truck for shipment to a large injection-molding plant in India. The unit provides a water-saving, low-maintenance solution that integrates with the customer’s existing cooling loop and supports stable process temperature control.

Project background

Customer: large Indian injection-molding/mold shop producing precision industrial parts.

Pain points: located in a water-restricted industrial park; existing open towers consume excessive water, foul easily, and generate noise and maintenance burdens. Customer required a compact, low-noise system that minimizes water treatment and can be paralleled with the current system.

On-site loading summary

After passing seal, heat-transfer, vibration and noise checks, the unit was secured by forklift, crated and banded on a flatbed. Logistics and QA teams supervised loading, photographed and archived shipping documents. The truck will take the unit to the designated port for export; customer or their agent will handle off-loading and installation at destination.

Key advantages (targeted)

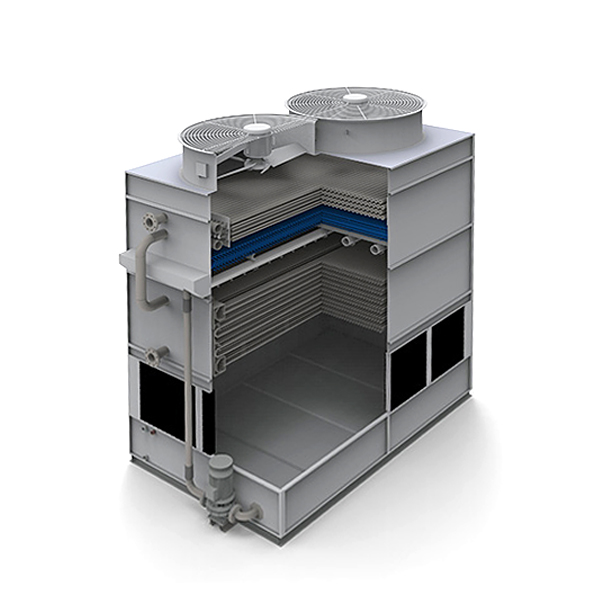

Closed-loop protection: Process water remains isolated from ambient air and external water, cutting fouling and contamination risks.

Water & chemistry savings: Much lower makeup water and reduced need for chemical treatment versus open towers.

Lower maintenance / longer life: Corrosion-resistant heat exchanger and limited exposure reduce cleaning frequency and downtime.

Stable, efficient cooling: Optimized heat-transfer area and airflow deliver tight temperature control for mold cooling and improved product quality.

Compact, low noise & modular: Small footprint and modular design allow parallel deployment for redundancy and capacity growth.

Easy integration: Standardized flanges, electrical interfaces and remote-monitoring options shorten installation and commissioning time.

Customer benefits

Reduced reject rate from improved temperature stability;

Lower water use and water-treatment expenses;

Fewer maintenance outages and higher line availability;

Lower total cost of ownership over the lifecycle;

Fast delivery with documented technical support.

After-sales support

Shipment includes installation drawings, P&ID, electrical wiring diagrams, factory test reports and a basic spare-parts list. We offer remote technical guidance and can dispatch field engineers for on-site commissioning under a service agreement.

Closing

This shipment marks another successful overseas delivery of an energy- and water-efficient cooling solution. For the full technical package (P&ID, performance curves, installation & commissioning SOP) or to schedule post-arrival support, please provide the local contact and estimated arrival date.