Advanced

The company has established a product quality control team, led by engineers, to strictly control the production process of products, ensure that the production process is traceable and that individual responsibilities are assigned to the production process.

Production Process Can Be Tracked

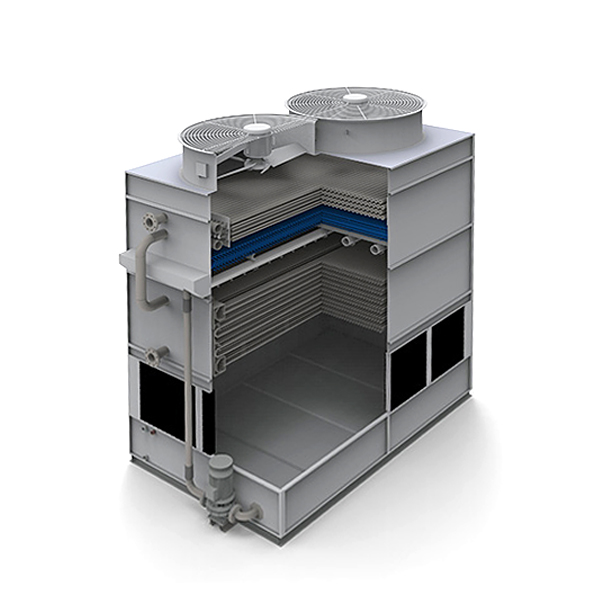

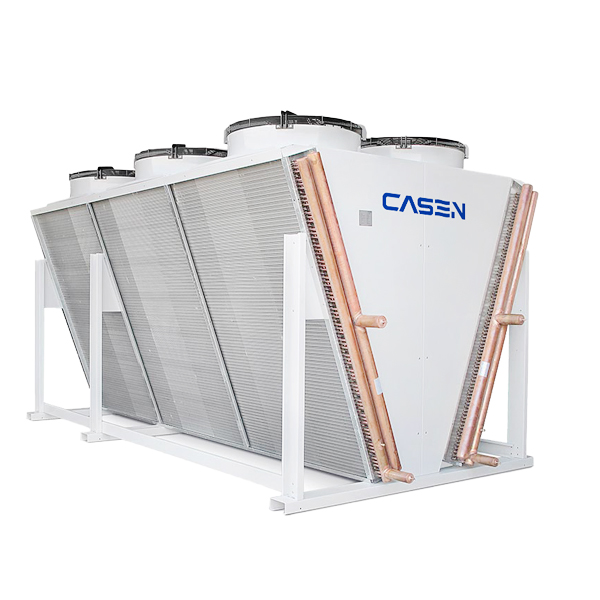

CASEN closed cooling tower is a standard device, from component quality inspection to whole machine inspection, standard pressure test and thermal performance test before delivery, all have high-standard equipment production and inspection processes. All devices are assembled and tested in the factory to ensure that the equipment can be quickly and easily installed and reliably operated at the site.

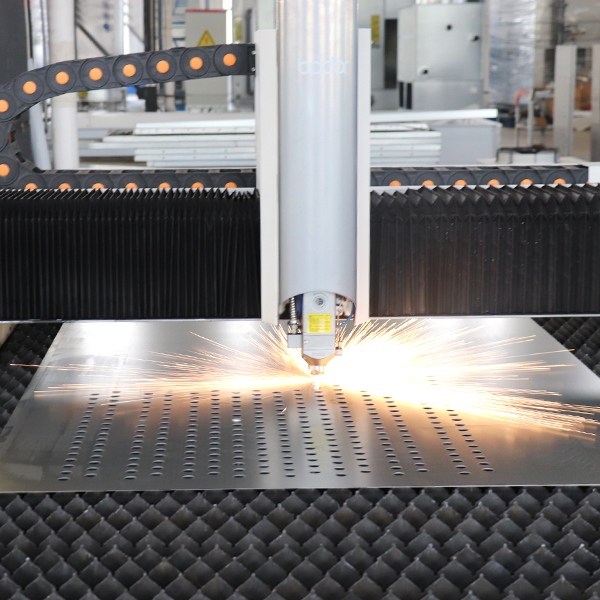

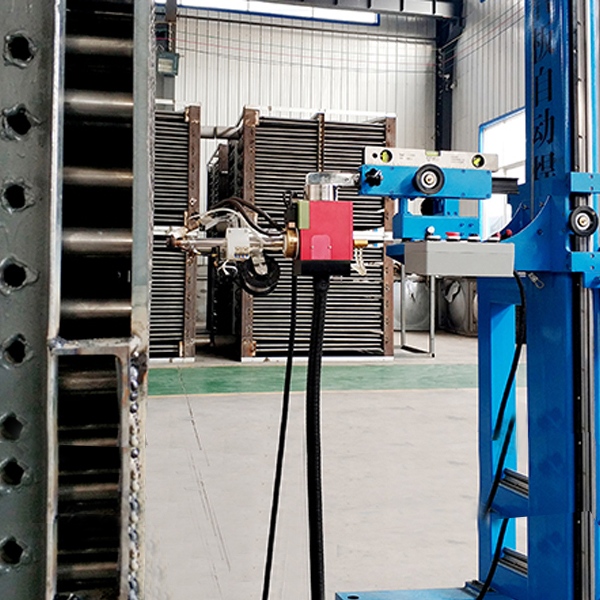

Laser Cutting Machine

Folding Machine

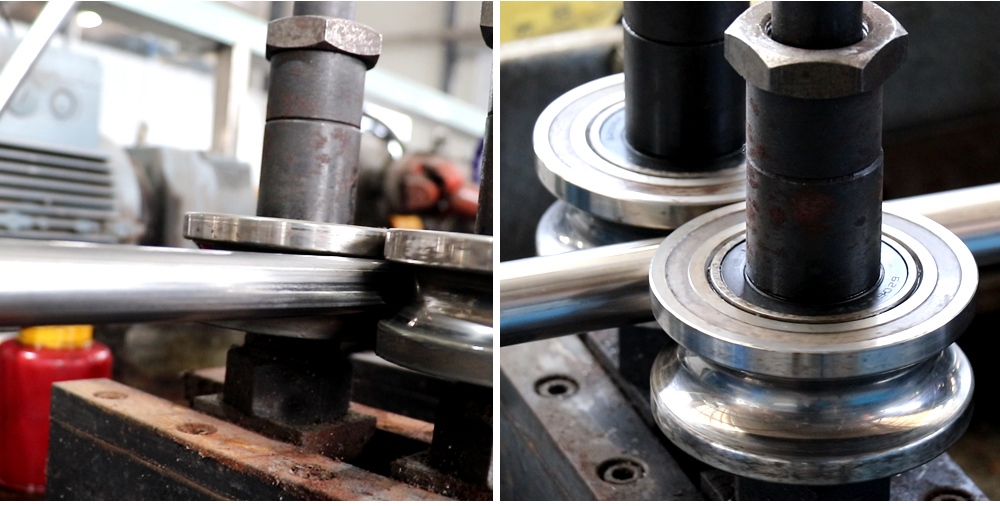

Coil Tube Making Line

Pipe Making Process

CASEN cooling tower is a standard unit constructed to provide many years of durable, dependable service with minimal maintenance requirements. Quality materials and workmanship are a key factor in meeting this objective. AII units are completely factory assembled and tested to ensure a quick and easy installation and reliable operation.

Sheet Materials

Foled Plate

Punching

Tubulation

Coil Bend

Coil Welding

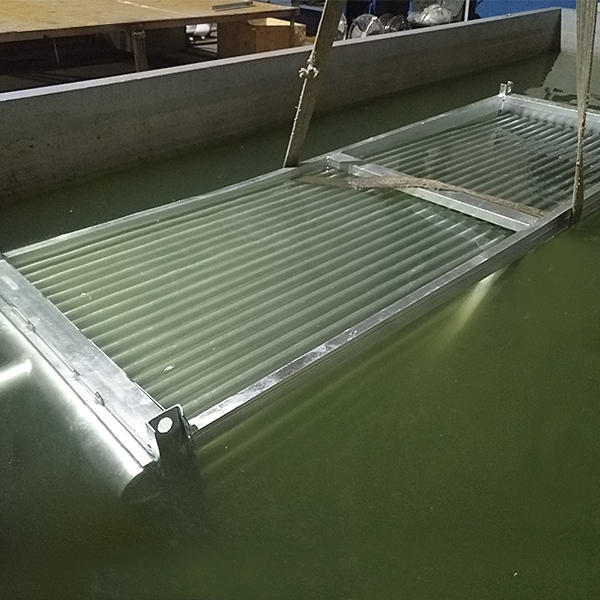

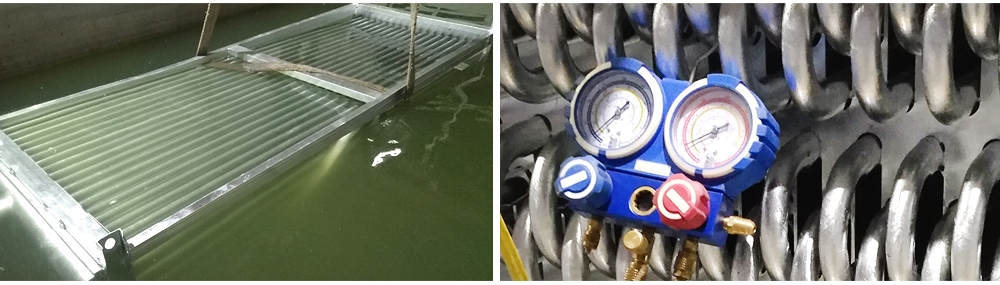

Pressure Test

Assemble

Product Testing

Sound ISO quality management system and strict factory inspection process (strict condenser pressure test, electronic control system inspection, equipment trial operation, etc.) ensure that the equipment meets the standards before leaving the factory.

Coil Pressure Test

Overall Equipment Debugging

Water testing