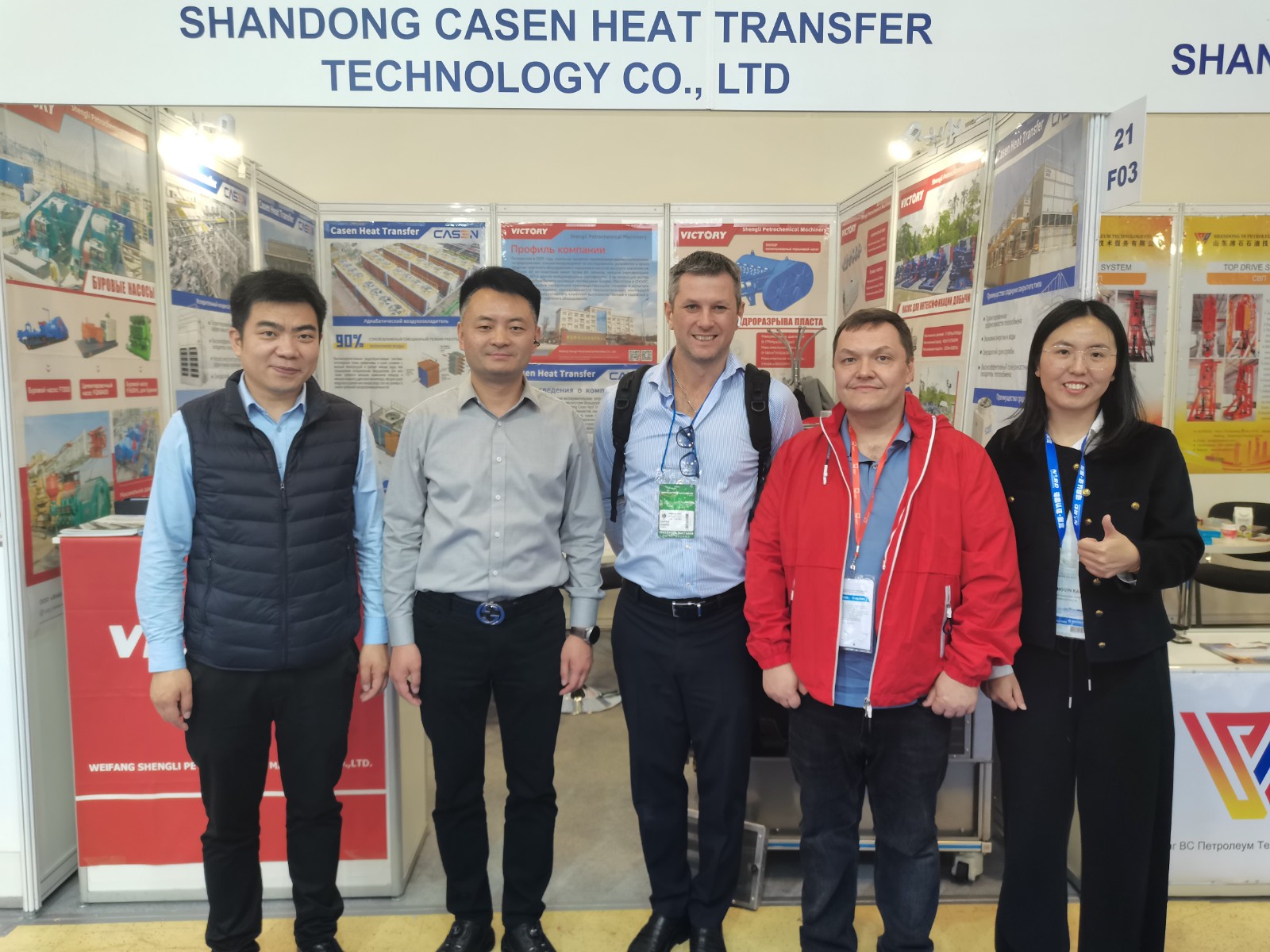

From April 14 to 17, 2025, the NEFTEGAZ International Exhibition for Equipment and Technologies for the Oil and Gas Industries was grandly held at the Expocenter in Moscow. As the most influential oil and gas exhibition in Eastern Europe, this year’s event covered 21,000 square meters, attracted 22,820 professional visitors, and brought together 573 exhibitors from around the world.

Shandong Casen Heat Transfer Technology Co., Ltd. was honored to participate in this exhibition, showcasing its latest generation of air cooler solutions alongside more than 1,800 industry pioneers from 41 countries.

1.Air Coolers: The "Cooling Weapon" of the Oil & Gas Sector

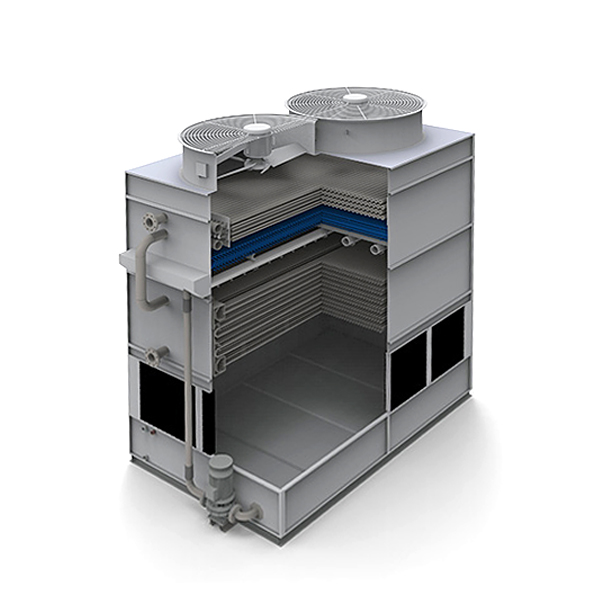

In oil and gas production and processing, high-temperature process gases must be cooled rapidly to meet the needs of subsequent separation, compression, and dehydration procedures.

Traditional water-cooling systems are often restricted by water availability, occupy large footprints, and are energy-intensive. In contrast, air coolers have emerged as the mainstream cooling solution in the oil and gas industry due to their water-free operation, flexible installation, and low maintenance cost.

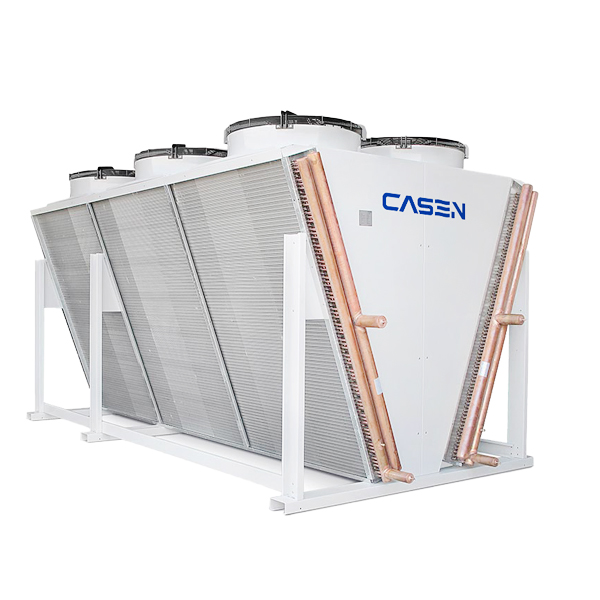

High Efficiency & Energy Saving: Equipped with high-airflow axial or centrifugal fans and efficient heat exchange fins, significantly improving thermal exchange performance per unit of power.

Eco-Friendly & Reliable: No water consumption or wastewater discharge, aligning with global trends toward sustainable production.

Highly Adaptable: Designed to withstand extreme climates and resist corrosion, ensuring stable operation in both frigid Siberian zones and hot Middle Eastern environments.

2. Casen Air Coolers: Technical Strength & Innovation Highlights

Since its founding, Casen has been committed to the R&D of high-end heat transfer equipment. At this NEFTEGAZ exhibition, the Casen team showcased three core technologies:

Multi-Channel Fin-Tube Heat Exchange Technology

Optimized fin spacing and angles improve air-side heat transfer coefficients.

Balanced tube bundle flow distribution reduces dead zones and effectively prevents condensation.

Smart Modular Fan System

Fans operate in parallel based on demand, with PLC control adjusting speed for energy savings.

Built-in fault self-diagnosis significantly shortens maintenance and troubleshooting time.

Anti-Corrosion & Anti-Freezing Coating (Patented)

Advanced nano-material coating enhances resistance to oxidation and icing in extreme conditions.

Service life extended by over 20% compared to industry peers.

These innovations drew wide attention from both local Russian and international clients, earning Casen a number of valuable inquiries and long-term cooperation opportunitie

3. Exhibition Highlights & Client Engagement

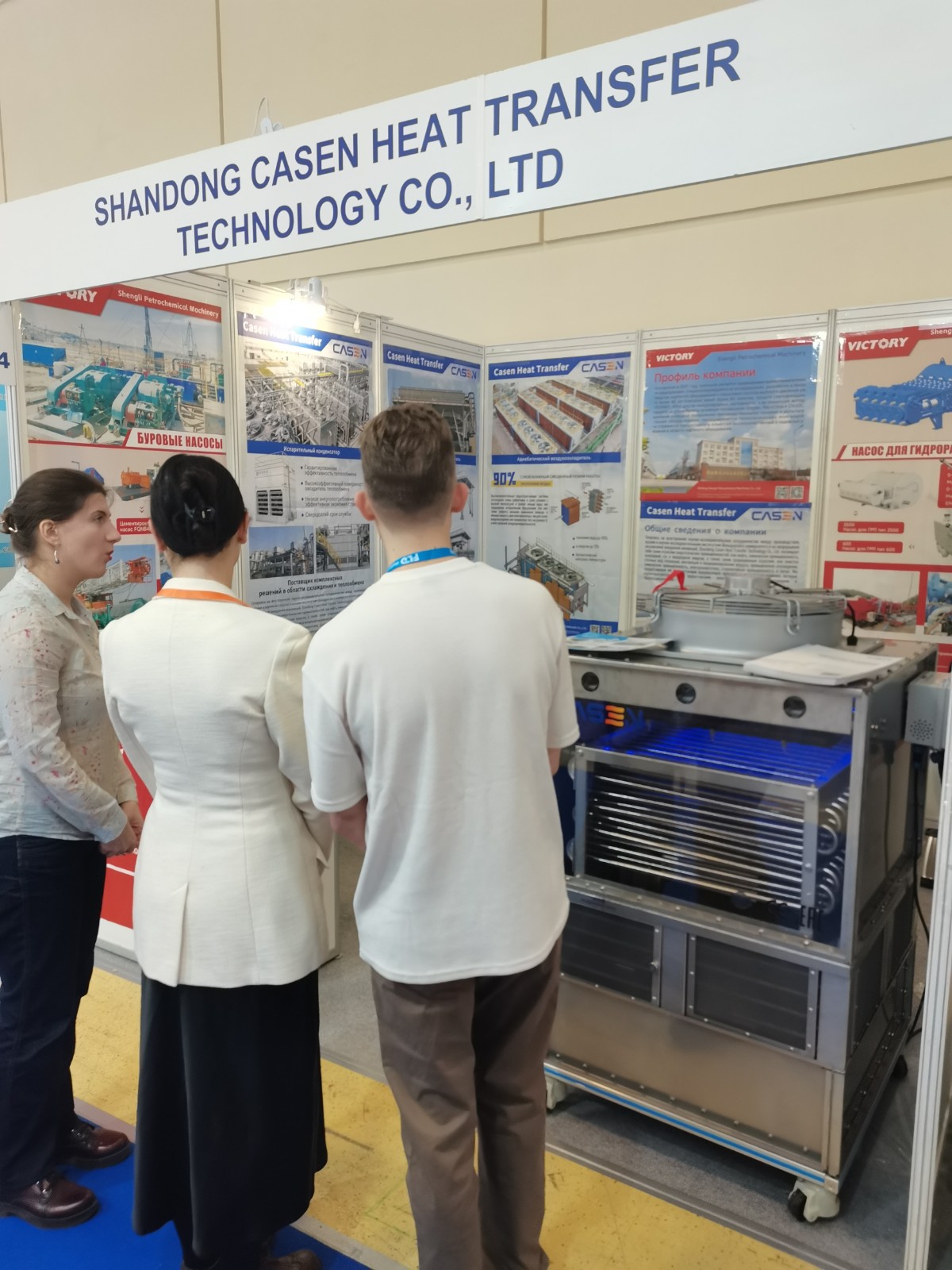

At the booth, Casen engineers engaged deeply with visitors, offering tailored air cooler model recommendations based on specific diameters and operational conditions.

Multiple petrochemical plants and gas field operators submitted inquiry forms on-site, covering applications such as waste heat recovery, compressor cooling, and nitrogen production systems.

4. Achievements & Outlook

Through this NEFTEGAZ exhibition, Casen successfully expanded its brand influence across Russia and the broader CIS market. The company also established post-show plans for technical evaluations and on-site visits with over ten key engineering firms.

Looking ahead, Shandong Casen will continue upholding its commitment to “Quality First, Innovation Driven,” constantly optimizing its air cooler technology to help the global oil and gas industry advance toward efficiency, sustainability, and intelligence.