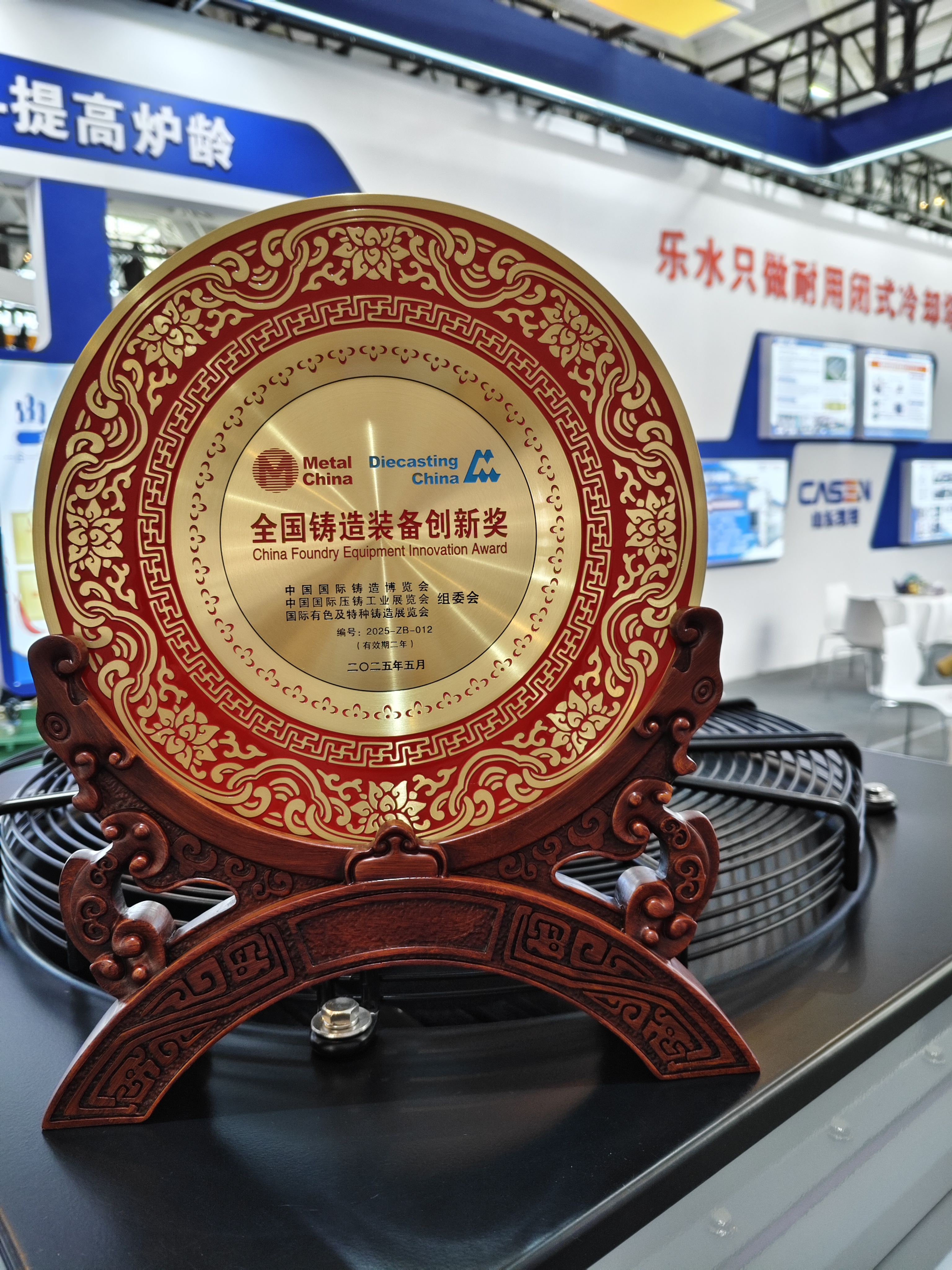

Tianjin, China, May 2025 — The 2025 China (Tianjin) International Foundry Expo—one of Asia’s premier gatherings for foundry, metallurgy,and heavy-equipment industries—concluded last week with resounding success for CASEN Cooling Technology Co., Ltd.. Over three days at the Tianjin Convention Center, CASEN’s booth became a hotspot for engineers, plant managers, and procurement specialists eager to explore cutting-edge cooling tower solutions.

Expo Overview

Drawing over 15,000 professional attendees and 350 exhibitors, the Tianjin Foundry Expo showcases the latest advances in casting processes, heat-treatment equipment, and auxiliary systems. Against the backdrop of China’s push for green manufacturing and energy efficiency, cooling tower technology has emerged as a critical enabler for foundries seeking to optimize thermal management and reduce operating costs.

CASEN’s Highlights & Innovations

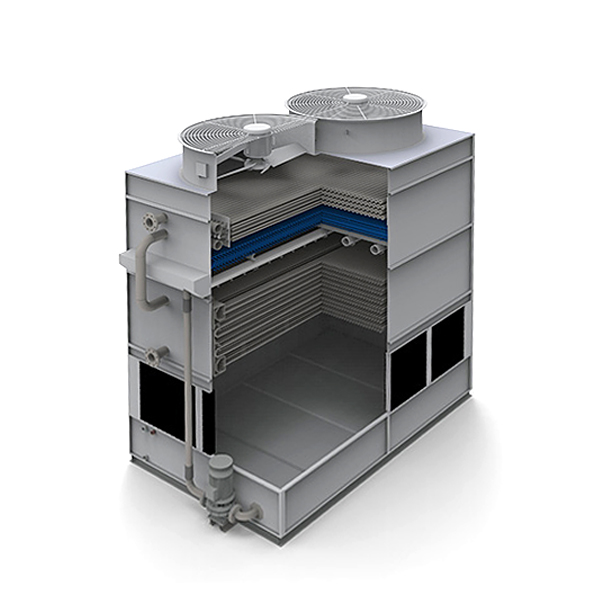

1.Modular, Rapid-Deploy Designs

Our pre-assembled cooling tower skids allow for streamlined shipping and on-site assembly—even in space-restricted foundry plants.

Visitors praised the ability to expand or reconfigure capacity simply by adding extra modules.

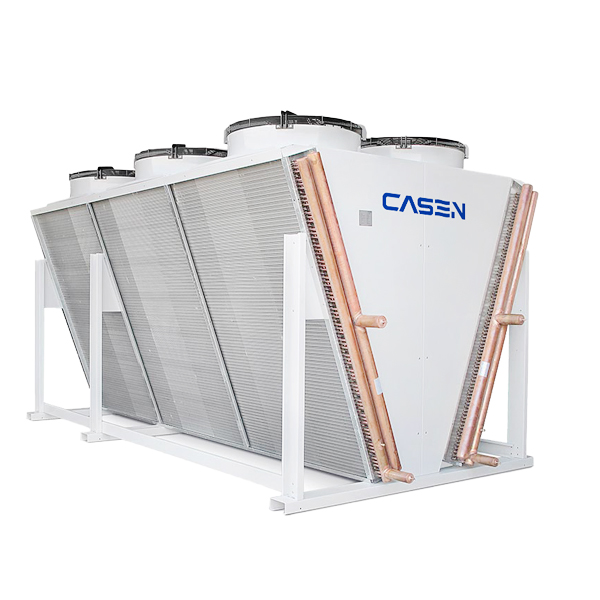

2.Superior Corrosion Resistance

All structural steel is treated with hot-dip galvanizing plus a two-coat paint system on welded areas, ensuring decades of maintenance-free operation in harsh, dust-laden environments.

Engineers noted how this approach outperforms conventional epoxy coatings under high-humidity, high-temperature service.

3.High-Efficiency Heat Transfer

Proprietary finned-tube bundles and low-noise axial fans deliver up to 15% greater thermal performance than standard designs—translating directly into lower water makeup and energy savings.

Multiple customers commented on the visible drop in operating temperatures during live demos.

4.Intelligent Control Integration

Our optional PLC-based control panels provide real-time monitoring of flow rates, fan speed, and water quality.

Several plant automation specialists expressed interest in integrating CASEN units with their existing SCADA systems for predictive maintenance.

Customer Feedback & Success Stories

Throughout the exposition, CASEN’s team conducted dozens of in-depth consultations. Highlights include:

·Tianjin Foundry Group: “CASEN’s modular approach means we can scale cooling capacity as our production lines expand. The galvanized steel finish is impressive—no flaking, no rust spots, even with continuous operation.”

·East China Metallurgical Plant: “The thermal efficiency gains are real. Since our plant trial, we’ve cut water makeup needs by 10% and reduced fan energy use by nearly 8%.”

·Overseas Delegations: Representatives from Southeast Asia and the Middle East expressed strong interest in CASEN’s turnkey package—particularly the ease of transport and quick commissioning.

Looking Ahead

Buoyed by the positive response in Tianjin, CASEN will:

Accelerate delivery of demo units to key customers for field trials.

Launch a localized service support center in outheast Asia and the Middle East by Q4 2025.

Continue R&D on advanced fill materials and noise-reduction fan technologies.

“This expo affirms that today’s foundries demand more than just equipment—they want reliable, efficient, and future-proof cooling solutions,” said President Jiao, CASEN’s Head of Sales. “We’re proud to demonstrate how our cooling towers answer that call.”