Safety is the lifeline of development and the firmest commitment CASEN makes to every employee and every customer.

On the occasion of China’s 24th National “Work Safety Month”, and in line with the theme “Everyone Speaks Safety, Everyone Knows Emergency Response — Identify Hidden Hazards Aroun

d You”, CASEN invited an external safety expert on June 19 to conduct a company-wide safety training session, injecting strong safety momentum into the company’s high-quality and sustainable growth.

d You”, CASEN invited an external safety expert on June 19 to conduct a company-wide safety training session, injecting strong safety momentum into the company’s high-quality and sustainable growth.

Before the training, our Production General Manager, Mr. Meng, delivered a mobilization speech emphasizing that safety is the cornerstone of CASEN’s development and the guarantee of employees’ well-being. He pointed out that this training aims to systematically raise employees’ safety awareness and urged everyone to seize this opportunity, learn attentively, apply what they learn in practice, and transform safety concepts into conscious actions to build a solid safety defense line together.

This training focused on key risk areas, covering core fire safety knowledge including fire prevention measures, methods for extinguishing initial fires, proper use of extinguishers and hydrants, evacuation route planning, and key points of emergency drills. Special education was also provided on seasonal risks such as rain, lightning, and heatstroke prevention.

In the practical session, the instructor visited the assembly lines and provided targeted safety guidance according to each process. By observing the actual workflows, the instructor accurately pointed out potential risks such as improper material handling postures, emergency stop button operations, and protective fixture use; demonstrated ergonomically correct actions and emergency response steps on site; and answered practical questions from employees about electrical inspections and PPE usage, helping everyone transform safety points into muscle memory.

In addition to theoretical learning, CASEN also organized a vehicle injury drill simulating a collision between a reversing truck and an employee caused by a blind spot. Witnesses promptly raised the alarm, and the emergency command center immediately activated the contingency plan. All teams responded swiftly and cooperated efficiently, effectively verifying the feasibility of CASEN’s vehicle injury response plan, on-site procedures, and cross-department coordination, further improving employees’ risk awareness and emergency response capability.

Safety is not just a temporary campaign but one of CASEN’s enduring core values: people-oriented, safety first, quality as the soul.

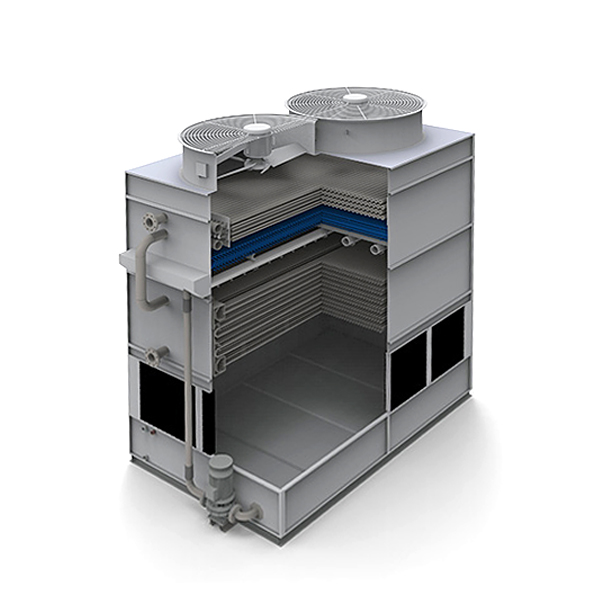

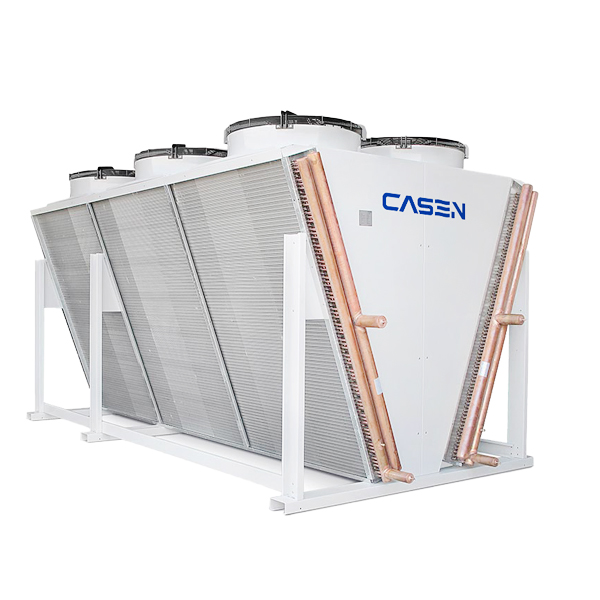

Driven by this belief, CASEN is committed to delivering safe, energy-efficient, and high-quality products to customers. Our cooling towers, air-cooled heat exchangers, and evaporative condensers are widely used in power, chemical, metallurgy, pharmaceutical, and food industries. With significant advantages such as high heat exchange efficiency, energy conservation, compact structure, and stable operation, our products have earned the trust of customers both at home and abroad.

As a trusted partner in the industry, CASEN focuses not only on technological upgrades and performance improvement but also on integrating safety and sustainability throughout the entire product life cycle — from design, manufacturing, and installation to maintenance — creating greater economic value and a more sustainable production future for our clients.

This safety training concluded successfully. By combining theory, practical on-site guidance, and emergency drills, it significantly improved employees’ risk recognition and emergency response capabilities, verifying the feasibility of our contingency plans and the effectiveness of team collaboration. CASEN hopes all employees will take this training as a starting point, transform safety knowledge into daily conscious actions, embed our corporate values into every production detail, and infuse our commitment to safety and quality into every cooling tower, air-cooled heat exchanger, and evaporative condenser, so we can jointly strengthen the safety barrier and empower the future of production!