Product Details

| Customization: | Available |

| Cooling Method: | Air Cooler |

| Ventilation Mode: | Mechanical Ventilation |

Shipping

| Shipping Cost: | Contact the supplier about freight and estimated delivery time. |

Basic Info

Model NO. | Casen | Material | Metal |

Air Contact Form | Dry | Air Contact Way | Closed |

Noise Level | Low | Application Fields | Industrial |

Certification | ISO, CE, CCC | Casing | Ss/Ulta-Galvanized |

Coil Tube | Ss | Fin | Ss or Aluminum |

Fan | Low Noise Type, Maintenance Free | Driven System | Weg Motors |

Capacity | Customized | Spraying Pump | Non |

Transport Package | Container | Specification | Customized |

Trademark | CASEN | Origin | China |

HS Code | 84198990 | Production Capacity | 150sets/Month |

Packaging & Delivery

| Package Size: | 2180.00cm * 2200.00cm * 3750.00cm |

| Package Gross Weight: | 10000.000kg |

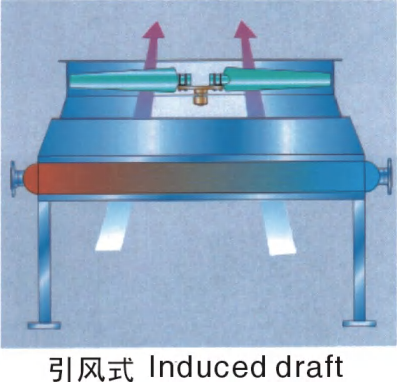

INDUCED DRAFT TYPE DRY AIR COOLER

The fan of the induced draft air cooler is located above the tube bundle. The air first flows through the tube bundle and then is extracted by the fan, creating a negative pressure environment. The air enters from below the tube bundle, is heated, and then is discharged through the fan.

Features

1.Uniform airflow

The air distribution is more uniform, with high operational stability.

2.Resistant to environmental interference

The fan and the wind tube have a shielding effect on the tube bundle, reducing the direct impact of rain, snow and sunlight on the tube bundle.

3.Low-temperature air return

The speed of hot air discharge is high (about 2.5 times that of the inlet), reducing the circulation of hot air risks.

4.Emergency capability

When the fan stops, natural convection can still maintain approximately 40% of the cooling load.

Design Structure And Features

LNVERTER CONTROLLED FAN AVAILABLE

The inverter fan runs more stably. In non-full operation mode, 30%~40% energy can be saved. Smaller motor size under the same performance.

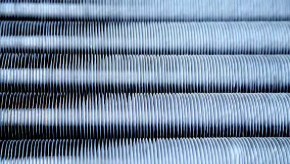

COIL WITH ALUMINUM FINS

Effectively improve the heat exchange efficiency. By adding fins on the surface of the heat exchange tube, the outer surface area (or inner surface area) of the heat exchange tube is increased, so as to achieve the purpose of improving the heat exchange efficiency.

EPOXY COATED FINS

The epoxy coating can improve the corrosion resis tance and surface oxidation resistance of the fins, and improve the use of fins.

Specification

Regulation model | Heat exchange area m² | Dimensions of the shape | Mass (in kilograms) | ||||

Fill with water | Metal | ||||||

A | B | C | "L, DR type fins" | "L-shaped fin" | "DR type | ||

GP6×3-6-128-1.6S-23.4/[]-Ⅰa | 128 | 6092 | 2985 | 1500 | 701 | 5922 | 6697 |

GP6×3-8-171-1.6S-23.4/[]-Ⅰa | 171 | 6092 | 2985 | 1500 | 939 | 7605 | 8639 |

GP3×3-4-42-1.6S-23.4/[]-Ⅰa | 42 | 3092 | 2985 | 1500 | 269 | 2632 | 2865 |

GP3×3-6-63-1.6S-23.4/[]- Ⅰa | 63 | 3092 | 2985 | 1500 | 437 | 3673 | 4022 |

GP3×3-8-84-1.6S-23.4/[]-Ⅰa | 84 | 3092 | 2985 | 1500 | 597 | 4660 | 5126 |

Packing & Delivery

Company Profile

Shandong Casen Heat Transfer Technology CO,.Ltd

Over the past decade, CASEN has rapidly developed in industrial evaporative and air-cooled cooling, committed to delivering high-quality, customized solutions. Our passionate, professional, and efficient team has earned strong customer trust and recognition.

CASEN upholds a culture of integrity, loyalty, and customer-first values. We believe customer satisfaction ensures sustainable growth, and we never take trust for granted. Innovation and environmental responsibility are at the heart of our development—driving energy-saving technologies and reducing carbon emissions.

With over 1,000 cases across industries, CASEN offers intelligent, energy-efficient solutions tailored to customer needs. We aim to make your work easier and the world greener, consistently delivering reliable, forward-thinking services. Thank you for your continued trust and inspiration.