Client industry: Fine chemicals manufacturing

Installation region: Chemical industrial park, Northern China

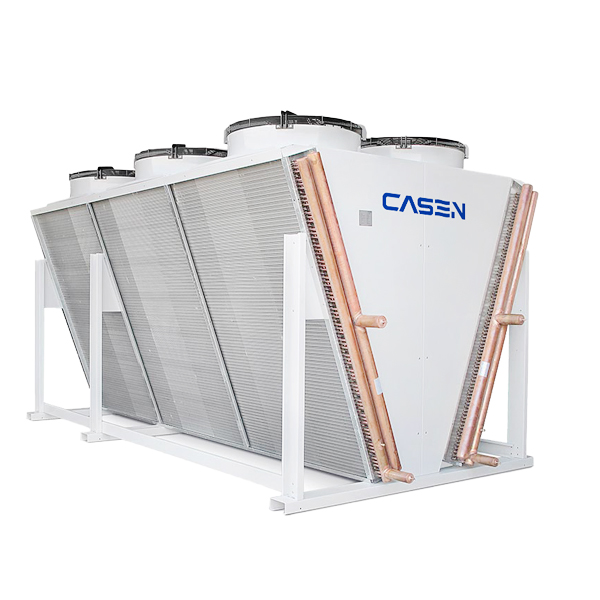

Equipment delivered: Casen custom forced-draft air cooler (fans located underneath) — single unit, rated ≈500 kW (≈143 RT), five-fan configuration, modular design

Project duration (typical): Design → manufacture → FAT → road transport → site installation & commissioning — approx. 6–8 weeks

Executive summary

Casen engineered, manufactured and delivered a tailor-made forced-draft air cooler for a fine-chemical producer located in a major industrial park in Northern China. The project addressed the customer’s urgent need for higher cooling capacity and reliable year-round operation during an expansion of production capacity.

The delivered unit—configured with five underslung fans, VFD control and corrosion-resistant materials—was fully tested at Casen’s facility, transported overland to the customer’s site, and commissioned on schedule. Early operation showed improved process temperature stability, reduced energy consumption, and simplified maintenance.

Project background & customer challenge

The client’s process involved continuous and batch reactors where precise temperature control was critical for product quality. Seasonal temperature swings in Northern China, with hot summers and freezing winters, placed extra demands on cooling equipment.

With production capacity increasing, the existing cooling system struggled during peak loads in summer and required frequent servicing. The customer needed a solution that could:

Deliver more cooling within a limited footprint

Operate reliably in extreme seasonal conditions

Resist corrosion from a chemical plant atmosphere

Reduce lifecycle operating costs and ease maintenance

Casen’s engineers analyzed the plant’s heat-load profile, site constraints, and climate conditions, then proposed a custom forced-draft air cooler optimized for these requirements.

Custom solution highlights

Five-fan, forced-draft configuration: Ensures strong, uniform airflow while allowing easy access to fans for servicing.

Variable frequency drives (VFDs) & smart control: Automatically adjust fan speed to match heat load, improving part-load efficiency and lowering electricity usage.

Corrosion-resistant construction: Hot-dip galvanized frame with stainless-steel in exposed or wetted areas; industrial-grade coating applied for extra protection in a chemical environment.

Modular, service-friendly design: Delivered in maintenance-oriented modules (heat-exchange banks, fan modules, electrical/control skids) for easy installation and future expansion.

Noise and vibration control: Aerodynamic ducting and fan selection validated by CFD to meet site noise limits.

Full FAT before shipment: Verified airflow, pressure drop, thermal performance, vibration, and electrical safety.

Manufacturing, logistics & commissioning

Production & QA: Detailed design completed rapidly, followed by strict-quality fabrication and finishing.

Testing & packing: Each module passed full factory acceptance testing. Units were crated and secured for long-distance truck transport.

Transport & installation: Overland delivery from Casen’s factory to the chemical park, coordinated with the client’s site schedule.

On-site commissioning: Mechanical installation finished within one week; electrical integration and testing in the second week. A 72-hour trial run confirmed performance before handover.

Performance & customer outcomes

Initial operation demonstrated:

Stable outlet temperature: Maintaining setpoint even during peak summer loads.

Energy savings: Around 15% reduction in power use compared to the previous cooling system (site/load dependent).

Maintenance efficiency: Modular design reduced inspection and servicing time by ~30%.

Reliability: Stable operation through the 72-hour trial with no performance drop.

Customer feedback: “Casen’s unit has improved our production stability, cut our electricity costs, and made maintenance faster and easier. The project was delivered on time and exactly as promised.”

Technical specifications (example unit)

Cooling capacity: ≈500 kW (≈143 RT)

Fans: 5 × underslung axial fans, VFD control

Structure: Hot-dip galvanized steel frame; stainless-steel exposed parts; protective coating

Features: Modular heat-exchanger banks, removable fan modules, integrated control panel, vibration isolation

Testing: FAT (airflow, pressure drop, delta-T), vibration, electrical safety

Conclusion

This project demonstrates Casen’s ability to adapt design to local climate, process needs, and site constraints, delivering a high-performance, durable and service-friendly cooling system. Casen continues to serve industrial clients in chemicals, refrigeration and manufacturing with engineered solutions that combine reliability, energy efficiency, and ease of maintenance.