Casen Heat Transfer Enables China’s First Large-Scale Green Methanol Cooling at Tiaonan Demo Project

In July 2025, Shanghai Electric’s landmark Tiaonan Wind-Power–Coupled Biomass Green Methanol Integrated Demonstration Project officially commenced commercial operation, marking China’s first “zero-to-scale” breakthrough in green methanol production. The inaugural phase will produce 50,000 tonnes per year of renewable methanol, destined for use as marine fuel aboard CMA CGM container vessels, initiating the “Tiaonan Production – Land–Sea Intermodal – Shanghai Bunkering” international supply chain.

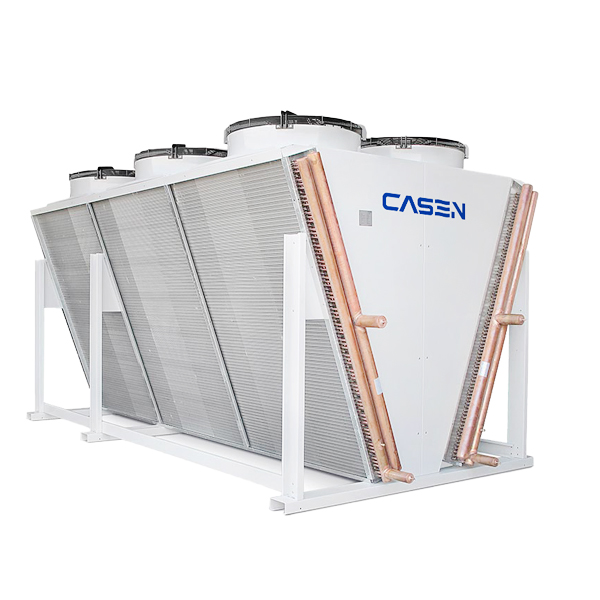

As the exclusive cooling-system supplier for the country’s first large-scale green methanol plant, Casen Heat Transfer Technology Co., Ltd. provided end-to-end thermal management solutions, from design and fabrication through commissioning and ongoing lifecycle service. Leveraging industry-leading expertise, Casen’s team ensured precise temperature control across key process units—hydrogen generation, vaporization, and synthesis—safeguarding stable operation and high-quality product output.

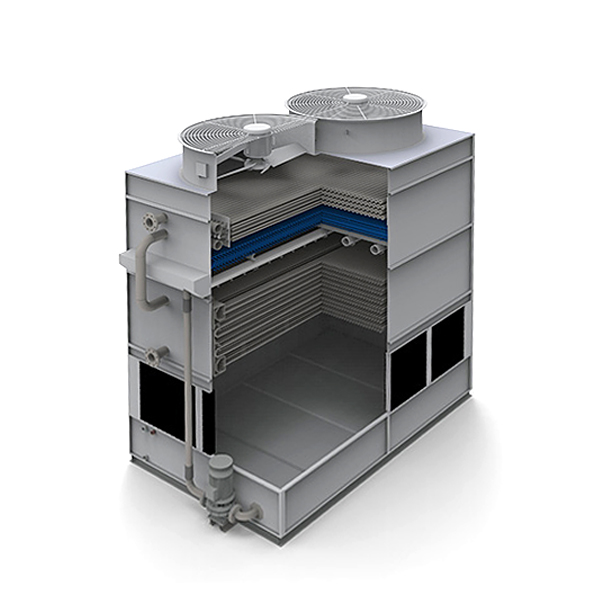

Precision Cooling for Cutting-Edge Green Methanol Synthesis

Green methanol synthesis involves multiple exothermic and temperature-sensitive steps. Faced with the challenge of maintaining tight thermal windows under highly variable load from wind-power fluctuations and biomass feedstock, the Tiaonan engineering team selected Casen’s bespoke shell-and-tube heat exchanger packages. Since start-up, the cooling system has held process temperatures within ±1 °C of setpoints, ensuring catalyst longevity and consistent methanol purity.

Innovative Heat Exchanger Design & Materials

Casen’s units are constructed from 316 L duplex stainless steel, providing exceptional corrosion resistance to biomass-derived impurities. Unique features include:

Enhanced Tube Bundles: Proprietary high-turbulence baffle design increases heat-transfer coefficient by 18 %, reducing exchanger footprint.

Zero-Purge Water Circuits: Closed-loop cooling minimizes makeup water consumption by over 90 %.

Modular Skid-Mount Construction: Pre-assembled, factory-tested modules sped on-site erection and reduced commissioning time by 30 %.

Full Lifecycle Service & Digital Intelligence

Casen deployed its PLC-based ThermalGuard™ monitoring system to provide real-time data on flow rates, temperatures, and fouling indicators. Predictive-maintenance algorithms forecast cleaning intervals, extending run lengths to 12 months between wash-down cycles. The technical team remains engaged through a three-year service agreement, offering remote diagnostics, periodic performance audits, and rapid-response support.

Quantifiable Benefits & Immediate Impact

Energy Savings: 22 % lower auxiliary power draw compared to conventional water-cooled systems

Water Conservation: 92 % reduction in cooling-water makeup requirements

Operational Uptime: 99.7 % availability through fluctuating renewable-power profiles

Maintenance Efficiency: Halved manpower needs for routine servicing

Noise Reduction: Vibration-isolated pumps and acoustically lined piping keep sound levels below 65 dB(A)

According to project data, the Casen cooling system achieved uninterrupted operation through the first quarter of full production, even during peak monsoon-season ambient conditions.

Pioneering Green Maritime Fuel Supply

By reliably supporting 50,000 tonnes per year of methanol synthesis, Casen Heat Transfer has laid the thermal-management foundation for China’s entry into green-methanol-fueled shipping. “Our precision cooling ensures every molecule of methanol meets the strictest quality standards required for marine engines,” said Li Wei, Technical Director at Casen Heat Transfer. “We’re proud to help China lead the global green-shipping revolution.”

Project leadership at Shanghai Electric echoed this sentiment: “Casen’s innovative design and lifecycle support were pivotal in achieving China’s first large-scale green methanol production,” stated Zhang Hui, Project Manager of the Tiaonan Demonstration. “Together, we’ve created a model for sustainable fuel manufacturing and international distribution.”

With the Tiaonan project now online, the “Tiaonan – Shanghai” bunkering corridor stands ready to demonstrate the viability of green methanol as the next-generation marine fuel, forging a new chapter in low-carbon shipping.