Executive summary

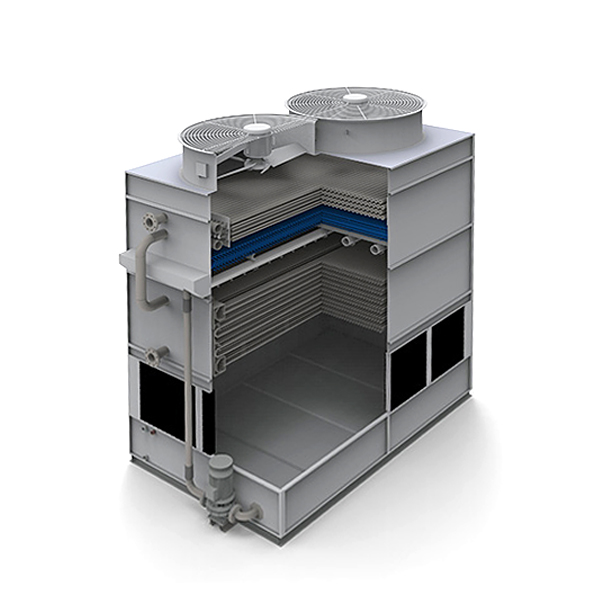

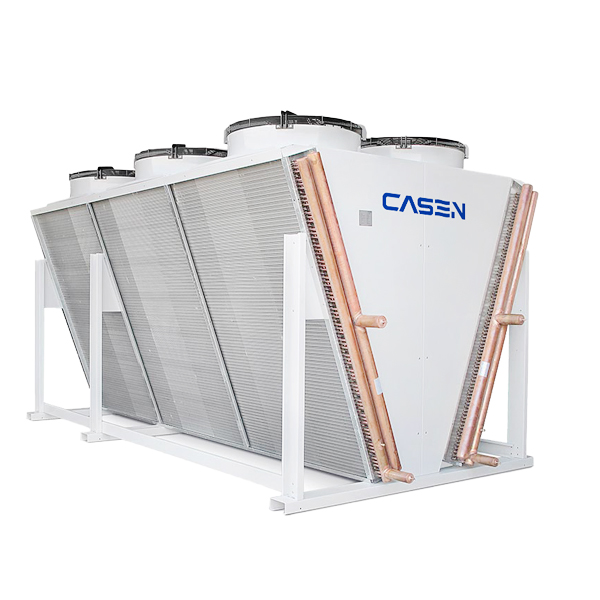

This case presents Casen’s counterflow closed cooling tower operating in Northern China. The units run reliably through cold seasons, demonstrating freeze-resilience, low energy use, and easy maintenance in harsh climates.

Project overview

Location: Northern China (cold winters, occasional icing, strong winds)

Type: Counterflow closed cooling tower, multiple units in parallel

Supplier: Casen Heat Transfer

Arrangement: Parallel multi-unit on platform for convenient piping and maintenance

Use: Process cooling / heat rejection for circulation systems

Design objectives & constraints

Provide stable year-round cooling with low energy and simple maintenance under limits of: low ambient temperature (ice risk), constrained site space, noise/vibration limits, and the need for corrosion resistance.

Key challenges

Preventing freeze and ice in spray headers, nozzles, and fill during low load or shutdown.

Avoiding exhaust recirculation that reduces performance in complex wind fields.

Balancing compact layout with adequate maintenance access.

Meeting local wind/snow/seismic structural requirements.

Selecting corrosion-resistant materials in wet zones.

Casen solutions & advantages

Anti-freeze strategy: segmented parallel piping + hot-water bypass for recirculation; electric trace heating and insulation on critical piping; freeze-resistant spray components.

High-efficiency compact design: extruded-fin, high-performance bundles reduce footprint; modular bundles for fast removal and maintenance.

Airflow optimization: on-site wind-aware layout, optional guide vanes or wind screens; VFD-driven fans for demand control and anti-ice operation.

Robust materials & structure: corrosion-resistant wet components, design verified to local wind/snow/seismic codes.

Maintenance friendly: accessible platforms, handrails, and monitoring (temp, level, flow, vibration) for remote alarms.

Operational benefits (actual feedback)

Stable winter operation without freeze damage.

Reduced maintenance downtime due to modular design and good access.

Lower energy use via efficient bundles and fan VFD control.

Low drift and compliant noise levels.

Typical technical template (to be completed)

Unit type: Counterflow closed tower (parallel units)

Airflow per unit: — m³/h

Heat duty per unit: — kW

Spray water temps (in/out): — °C / — °C

Fill type; fan type; tube/fin material; anti-freeze measures.

Maintenance recommendations

Establish winter SOP (bypass logic, trace heating, drainage), online monitoring, regular chemical treatment, and seasonal full inspections.

Conclusion

Casen’s counterflow closed towers provide proven freeze resistance, operational economy, and maintainability for Northern China installations. We can supply tailored designs, drawings, and on-site commissioning support on request.