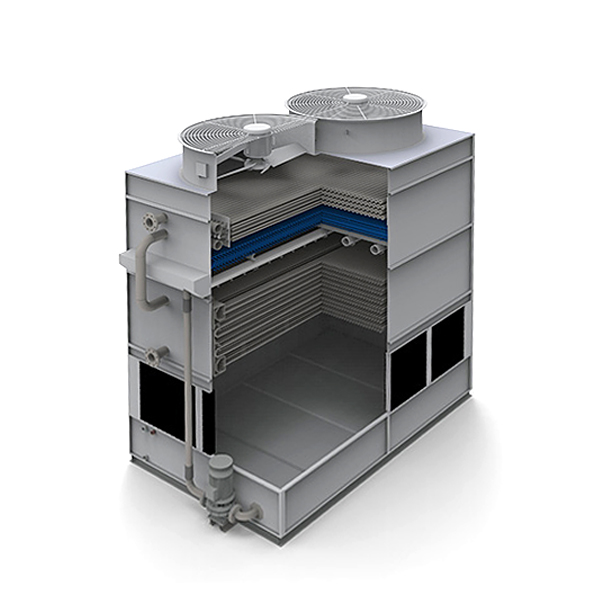

In India’s hot and humid textile heartland, process cooling has traditionally depended on large water-cooled shell-and-tube condensers—systems that demand constant make-up water and intensive maintenance. Faced with escalating municipal water tariffs and stringent effluent regulations, forward-looking mills are now turning to evaporative condensers for their closed-loop reliability, reduced water makeup, and lower lifecycle costs.

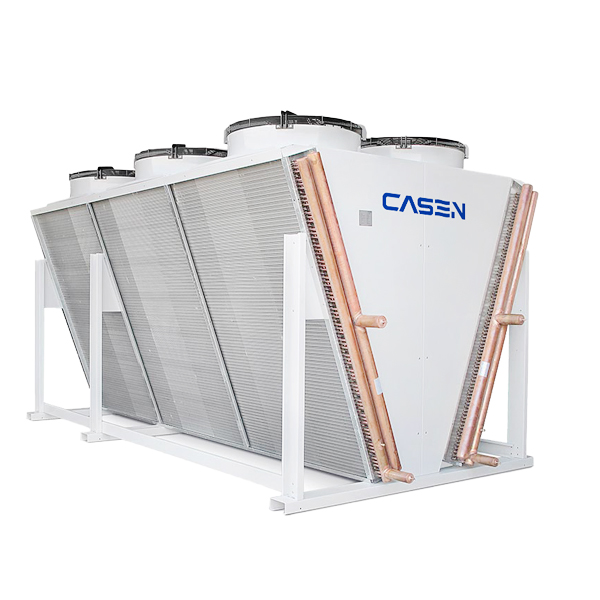

Recently, Shandong Casen Heat Transfer Technology Co., Ltd. delivered and commissioned five custom evaporative condensers at a major textile manufacturing facility near Pune,Maharashtra.

Project Highlights:

·Site Conditions: Average ambient wet-bulb 26 °C, annual relative humidity 65–85%, municipal water hardness > 350 ppm.

·Application: Condensation of high-pressure steam from two 10 MW steam turbines.

·Capacity: 4 × 1,200 kg/h steam load.

·Design Approach: Hybrid air-and-water cooling with drift eliminators to minimize drift losses (< 0.002% of circulation rate).

Key Features & Benefits

1.Closed-Loop Condensation: Process steam is condensed on internal coils; cooling water recirculates within the unit, avoiding direct steam-air contact and eliminating secondary contamination.

2.Water Makeup Reduction: Compared to conventional shell-and-tube systems, the evaporative condenser cuts makeup water demand by up to 70%, saving approximately 25,000 m³ of water annually.

3.Low Maintenance: Corrosion-resistant PVC fill media and self-cleaning drift eliminators reduce fouling; routine blow-down automated to maintain water quality, slashing manual maintenance by 50%.

4.Energy Efficiency: Variable-frequency condenser recirculation pump and axial fans optimize power draw under varying loads, reducing parasitic power consumption by 15%.

5.Compliance & Noise Control: Equipped with low-noise fan modules (≤ 68 dB(A) at 10 m) and a closed-circuit treatment loop that meets India’s National Green Tribunal discharge standards.

Rapid Delivery & Commissioning

From order placement to full operation, Casen’s team completed engineering, fabrication, and on-site commissioning in just 42 days—a new benchmark for turnkey cooling solutions in the region. The customer reported:

“Casen’s evaporative condensers have dramatically reduced our water and power costs while ensuring stable, continuous turbine operation. This upgrade directly supports our sustainability targets.”

Looking Ahead

Casen remains dedicated to delivering innovative, resource-efficient cooling technologies across India and the broader South Asian market. We look forward to partnering with more industrial leaders on their journey toward greener, more cost-effective operations.