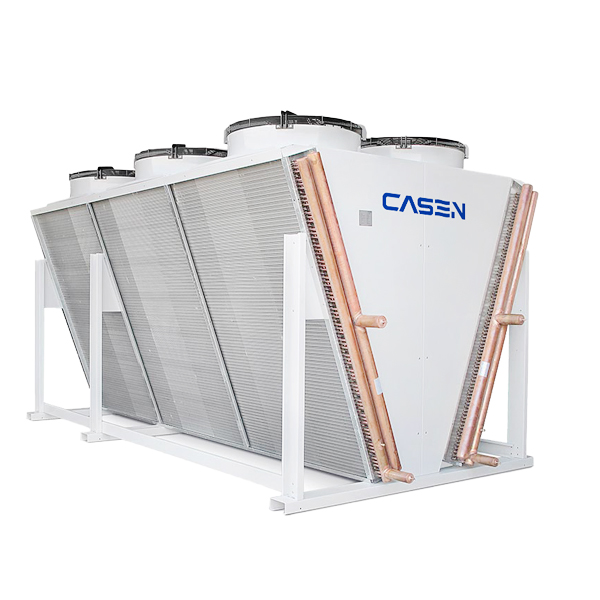

Surabaya, Indonesia – May 2025 — CASEN Heat Transfer Technology Co., Ltd. has partnered with one of Indonesia’s foremost pharmaceutical manufacturers to commission two of its advanced stainless steel evaporative condensers at a newly inaugurated sterile injection facility outside Surabaya. Engineered for peak performance in tropical climates, the installation delivers precise temperature control, remarkable energy savings, and entirely chemical free operation—setting a new benchmark for sustainable industrial cooling.

Precision Cooling for Critical Processes

In pharmaceutical production, even minor temperature fluctuations can compromise product integrity. Faced with the challenge of maintaining sub10 °C chilled water under continuous high load conditions, the plant’s engineering team turned to CASEN’s proven evaporative condenser technology. Since start up, the system has held chilled water temperatures at a consistent 9 ± 1 °C, ensuring a stable, GMP compliant environment for sensitive sterile fill operations.

Engineered for Reliability and Efficiency

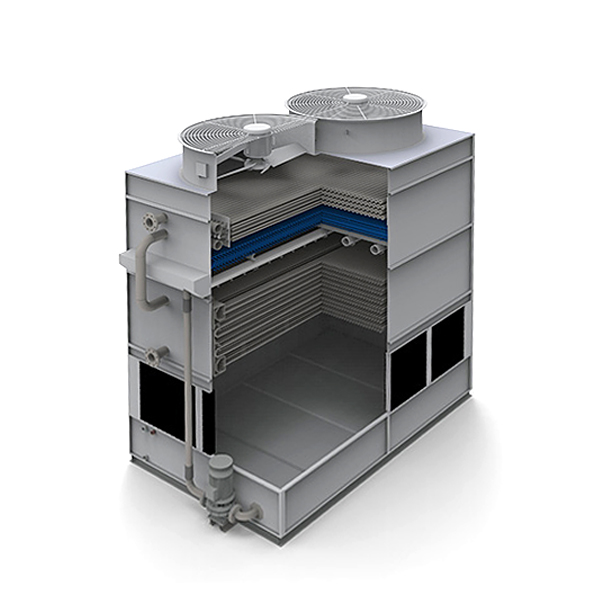

CASEN’s evaporative condensers are built from 100 % 316L marine grade stainless steel, offering unrivaled resistance to corrosion and fouling. Unlike conventional units, these condensers feature CASEN’s proprietary Wave Mesh fill media, which expands the evaporation surface by 15 %, driving faster heat removal while minimizing footprint.

A key differentiator is the zero chemical water treatment approach. By harnessing filtered river water and recapturing over 99.995 % of drift, the system eliminates harmful discharge and extends maintenance intervals—requiring just two wash down cycles per year. Intelligent PLC based controls provide real time monitoring of flow, temperature, and water quality, enabling predictive maintenance and uninterrupted operation.

Tangible Benefits, Immediate Impact

·Energy Reduction: Over 20 % annual electricity savings compared to traditional air cooled systems

·Space Optimization: Roof mounted design liberates valuable floor area for production

·Operational Simplicity: Bi annual servicing and remote diagnostics slash downtime and labor costs

·Environmental Stewardship: Zero chemical cooling and ultra low water loss uphold sustainability goals

·Quiet Performance: Vibration isolated mounts and acoustically tuned fans keep noise below 68 dB(A)

Plant management reports that, in the first quarter post installation, the condensers delivered seamless performance through peak ambient wet bulb conditions, with no unplanned interruptions or water quality issues.

A Model for Sustainable Industry

This project exemplifies CASEN’s mission to drive greener, more efficient cooling across industries. With installations now supporting electronics manufacturing, food processing, precision machinery, and pharmaceuticals throughout Southeast Asia, CASEN continues to lead the transition toward sustainable process cooling—combining cutting edge materials, innovative design, and digital intelligence.

“Partnering with CASEN has transformed our cooling strategy,” said the plant’s Engineering Director. “We now enjoy stable process temperatures, lower energy bills, and the confidence of an eco friendly, low maintenance system—exactly what our growing production demands.”