I. Background

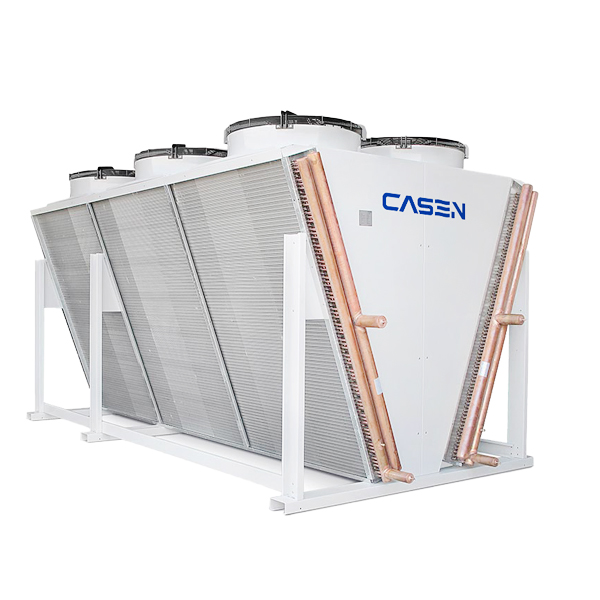

In early 2025, a major beverage group in São Paulo needed a compact, energy-efficient condenser for a new 1,400 kW low-temperature bottling line. They sought reliable operation, corrosion resistance, and strong local support. After comparing suppliers, Casen’s proposal was selected.

II. Equipment & Solution

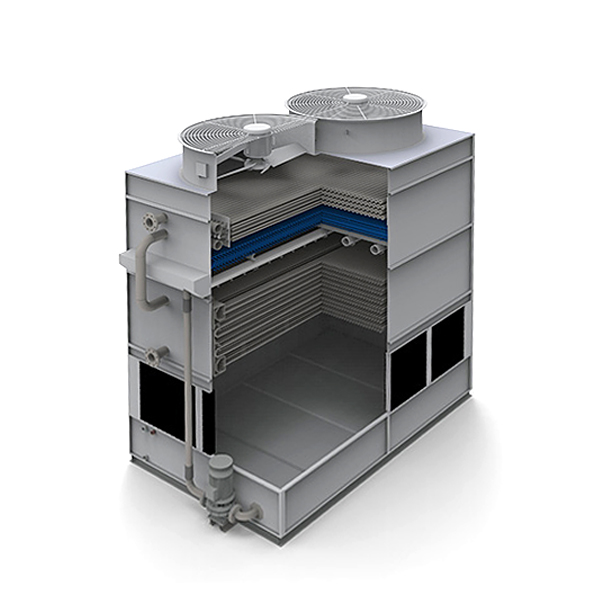

Casen recommended the KEN-1500 series evaporative condenser, to match three screw compressors. Key features:

·Capacity: Up to 1,500 kW.

·Evaporative Design: Lowers condensing temperature by spraying water over flame-retardant PVC honeycomb fill.

·Materials: Seamless copper coils; heavy-gauge galvanized steel casing with multi-layer anti-corrosion paint.

·Energy Savings: Over 15 % lower consumption than equivalent air-cooled units.

·Compact Footprint: 3.4 m × 2.0 m × 2.6 m (≈7 m² roof footprint).

After technical review, the customer approved KEN-1500 for its efficiency in high-humidity, salt-air conditions.

III. KEN Advantages

High Efficiency: Evaporative cooling leverages water’s latent heat, cutting energy use by ≥10 %. Proprietary fill design maximizes heat transfer.

Durability: PVC fill resists fouling and corrosion. Galvanized, painted casing withstands humidity and salt air for a 15-year service life.

Compact Design: Requires only 7 m² rooftop area; no separate cooling tower needed.

Quiet & Low-Maintenance: Centrifugal fan keeps noise <65 dB(A). Modular panels allow cleaning within one hour; no complex water treatment needed.

Smart Control: PLC monitoring, timed flushing, automatic makeup water, and water-level alarms prevent scaling. Remote DCS/SCADA integration enables 24×7 oversight.

IV. Results & Benefits

Since commissioning in March 2025:

Annual Savings: Approximately 180,000 BRL, thanks to a 12 % reduction in power compared to air-cooled design.

High Reliability: 99.5 % uptime over three months, zero production interruptions.

Reduced Maintenance: Self-flushing and fouling-resistant fill allow quarterly cleaning, lowering labor.

Low Noise & Environmental Compliance: Quiet rooftop operation avoided neighbor complaints. The plant awarded Casen’s solution as “efficient, low-noise, and eco-friendly.”

The project manager remarked, “Casen guided us from selection to startup. The KEN-1500 exceeded expectations in energy savings, stability, and maintenance ease. We plan to use Casen’s solutions in other facilities.”

V. Conclusion & Next Steps

This São Paulo installation highlights the KEN-1500’s ability to deliver high performance, durability, and reliability. It fulfilled the client’s strict requirements and strengthened Casen’s reputation in South America.

Looking Ahead:

Regional Expansion: Additional KEN-1500 units will be installed in Salvador and Recife in late 2025.

R&D Enhancements: A water-saving fill and advanced IoT monitoring will be launched by year-end 2025, reducing water usage and simplifying upkeep.

Local Service Expansion: Casen will open a technical center near São Paulo to stock spare parts and station engineers for rapid support.

Casen’s KEN evaporative condenser—combining high efficiency, low noise, easy maintenance, and intelligent control—is now a preferred choice for beverage, food processing, and cold-chain customers. For similar cooling needs, please contact Casen for a customized, energy-efficient solution.