1. Factory Background

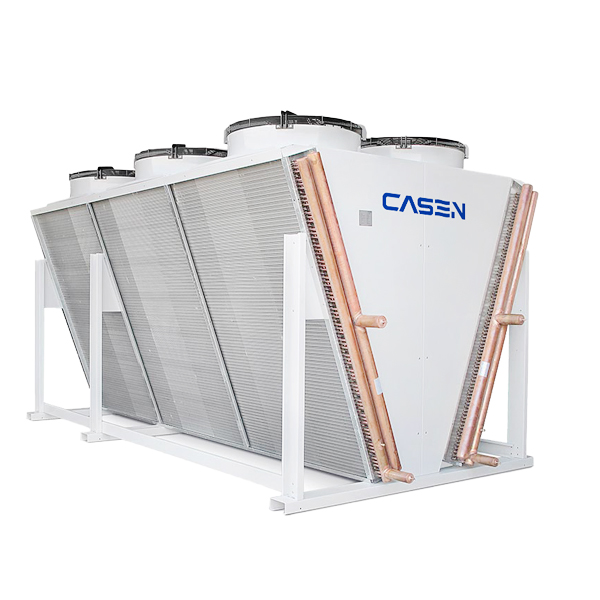

The juice factory is located in an industrial area in Malaysia, with a daily output of over 500,000 bottles. Due to the high temperature and high humidity in the local area, the original cooling equipment was inefficient and had high energy consumption. The factory chose the CASEN closed cooling tower to meet the needs of efficient cooling and energy saving.

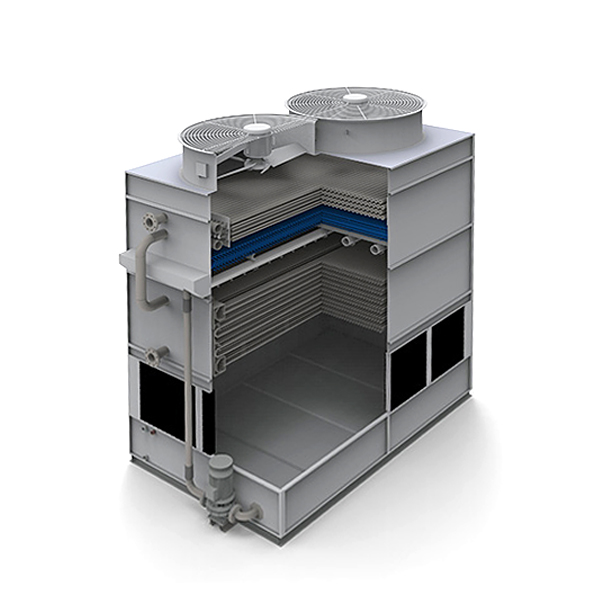

2. Advantages of the CASEN closed cooling tower

(1) Efficient cooling

Advanced heat exchange design, adapted to high temperature and high humidity environment, cooling efficiency increased by 20%.

(2) Energy saving and consumption reduction

Energy saving of 15%-25% compared to traditional equipment, and intelligent control system further reduces energy consumption.

(3) Low maintenance cost

Simple structure, easy maintenance, corrosion-resistant materials extend service life.

(4) Strong adaptability

Modular design, adaptable to high humidity environment, support future capacity expansion.

(5) Environmental protection and water saving

The circulating water system reduces water consumption, and is equipped with a water treatment device to ensure water quality.

3. Summary

The CASEN closed cooling tower successfully solved the cooling problem of the juice factory, significantly improved efficiency and environmental protection performance, demonstrated its technical strength in the field of industrial cooling, and laid the foundation for promotion in the food and beverage industry.