1. Factory Background

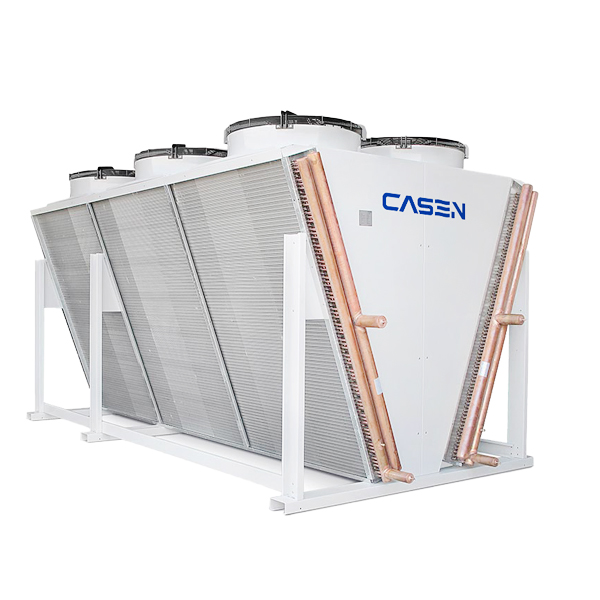

The chemical plant is located in Southeast Asia and mainly produces synthetic ammonia and urea, with an annual output of more than 500,000 tons. Due to the high temperature and high humidity in the local area, the traditional cooling equipment is inefficient and consumes a lot of water. The factory urgently needs an efficient and water-saving cooling solution. In the end, the factory chose the CASEN closed cooling tower.

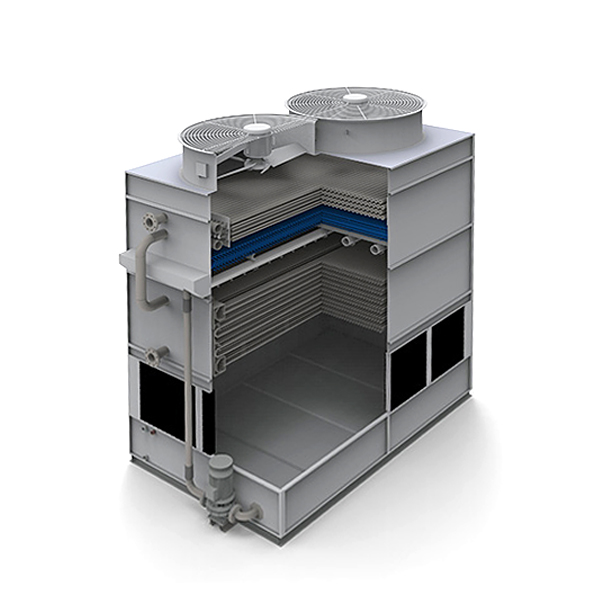

2. Advantages of CASEN closed cooling tower

-High efficiency and energy saving: The advanced heat exchange design is adopted to maintain efficient cooling in high temperature and high humidity environment, which saves about 25% energy compared with traditional open cooling towers.

-Water-saving and environmental protection: The closed design reduces water evaporation and drift water loss, saving about 30% water each year, which complies with local environmental protection policies.

-Strong corrosion resistance: The use of stainless steel materials and anti-corrosion coatings can withstand the highly corrosive environment of chemical plants, especially suitable for the humid and high-salinity environment in Southeast Asia.

-Low maintenance cost: The closed structure prevents impurities from entering the cooling system, reduces the cleaning frequency, and the intelligent monitoring system reduces the failure rate.

-Customized design: Provide customized solutions according to factory needs, the equipment occupies a small area and adapts to limited installation space.

3. Summary

CASEN closed cooling tower helped the chemical plant solve the cooling problem in high temperature and high humidity environment, significantly reducing energy consumption and water consumption. Its advantages of energy saving, environmental protection, corrosion resistance and low maintenance demonstrate CASEN's technical strength in the field of industrial cooling and lay the foundation for future expansion in the Southeast Asian market.