-Industry Background:

In the beer production industry, temperature control is a key factor in determining product quality. From malting, fermentation to cooling and filling, each link has strict temperature requirements to ensure the accuracy of the brewing process and the consistency of the beer flavor.

-Project Overview:

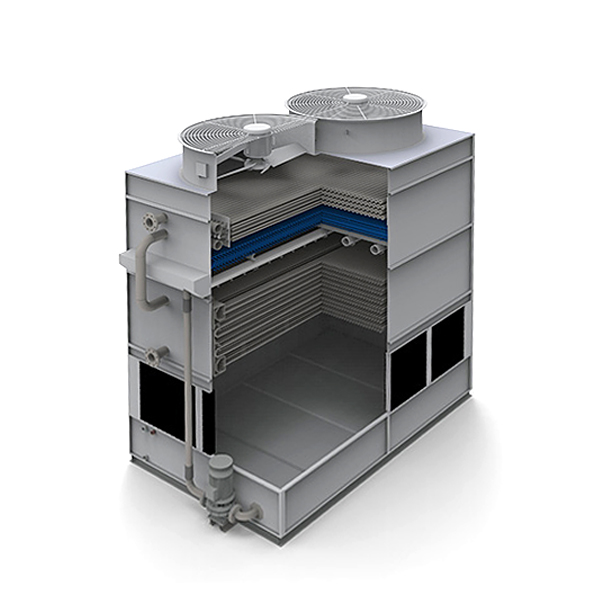

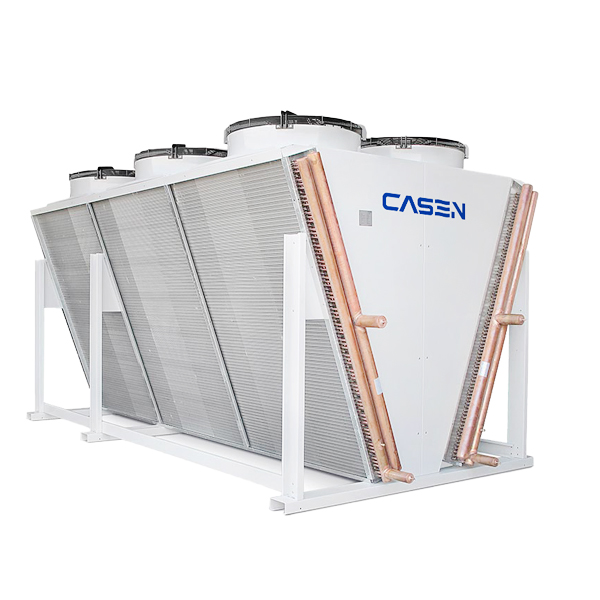

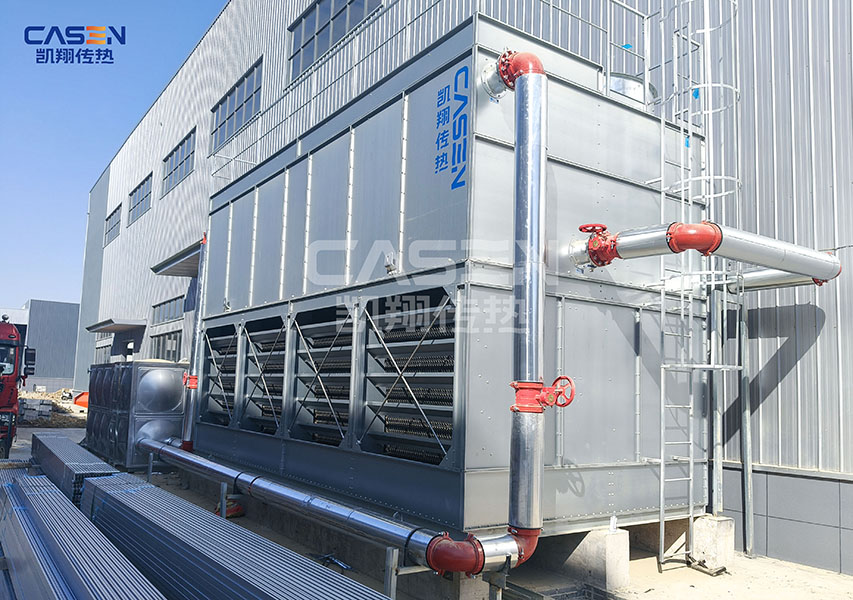

This project is located in Sri Lanka and is a core cooling system renovation project for a large brewery. Due to the high temperature and high humidity environment in the region, the company needs a cooling system that can adapt to climatic conditions, precise temperature control and reliable performance to improve the stability and efficiency of the beer production line. After multiple investigations, the customer finally chose the closed cooling tower as the core equipment.

-Core Advantages:

1. Accurate temperature control

2. Reliable performance and reduced maintenance downtime

3. Ensure product stability and maintain strict production standards

-Summary:

The successful application of the Sri Lanka Cooling Tower Project in the field of beer production provides stable and reliable cooling support for the production of local breweries. Its precise temperature control capability, excellent reliability and low maintenance requirements not only help companies ensure the high quality of their products, but also effectively improve operational efficiency and market competitiveness. This case demonstrates the wide applicability and excellent performance of closed cooling towers in the food and beverage industry, and also sets a benchmark for similar projects in the future.