Product Details

Customization:Available

Type:Air-Cooled

Cooling Water:Industrial Water

Basic Info

| Model NO. | Casen | System Type | Closed System |

| Fans Species | Frequency Fan | Noise Level | Low |

| Application Fields | Machinery | Certification | ISO, CE, SGS |

| Condition | New | Casing | Galvanized or Stainless Steel |

| Fan | Low Noise | Fin Tube | Galvanized or Stainless Steel |

| Medium | Gas or Liquid | Transport Package | Container |

| Specification | 100 ton | Trademark | CASEN |

| Production Capacity | 200 Sets/Month | HS Code | 84198990 |

Product Description

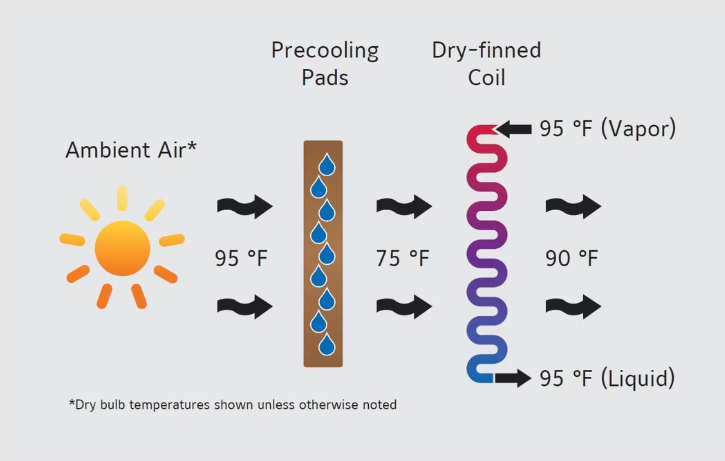

Adiabatic Operating Principle: Wet or Dry Operation

Efficient FACS adiabatic condensers with hydroBLU™ Technology can be operated either

wet or dry. Both modes provide excellent performance with a small footprint and low operating costs.

The cooling limit (the theoretically best possible condensing temperature/pressure for the system) is tied to the wet bulb the temperature of the ambient air.

Thermal Efficiency

Increased Thermal Performance, Lowers Total Cost of Ownership At peak ambient temperatures, the air entering the finned heat the exchanger is pre-cooled by wetted cooling pads to a temperature approaching the wet-bulb temperature, without the aerosol formation and without applying water to the finned surface.

The pre-cooling process maintains the required condensing temperatures at peak ambient conditions. The adiabatic process significantly increases the thermal efficiency of the condenser with minimal water usage.

The increased thermal performance at peak ambient conditions lowers the total cost of ownership. The reduction in compressor energy usage permits higher COP's, with a significantly reduced footprint.

Evaporative condensers use water as the evaporative cooling source throughout the year. The adiabatic alternative only uses water at peak ambient conditions thereby significantly reducing or eliminating water usage, water treatment, chemicals, sewage, and the costs associated with each.

Technical Data

| Specifications and parameters of 1.6MPa series horizontal carbon steel tube bundles | |||||

| Tube bundle model | External dimensions | Number of pipe rows | |||

| A | B | C | |||

| GP12×3-4-172-1.6S-23.4/[ ]-Ⅰa | 12092 | 2985 | 1500 | 4 | 4 |

| GP12×3-4-172-1.6S-23.4/[ ]-Ⅱa | |||||

| GP12×3-6-258-1.6S-23.4/[ ]-Ⅰa | 6 | 6 | |||

| GP12×3-6-258-1.6S-23.4/[ ]-Ⅱa | |||||

| GP12×3-8-344-1.6S-23.4/[ ]- Ⅰa | 12092 | 2985 | 1500 | 8 | 8 |

| GP12×3-8-344-1.6S-23.4/[ ]-Ⅱa | |||||

| GP10.5×3-4-150-1.6S-23.4/[ ]-Ⅰa | 10592 | 2985 | 1500 | 4 | 4 |

| GP10.5×3-6-226-1.6S-23.4/[ ]-Ⅰa | 6 | 6 | |||

| GP9×3-4-129-1.6S-23.4/[ ]-Ⅰa | 9092 | 2985 | 1500 | 4 | 4 |

| GP9×3-6-193-1.6S-23.4/[ ]-Ⅰa | 6 | 6 | |||

CASEN Adiabatic Air Cooler

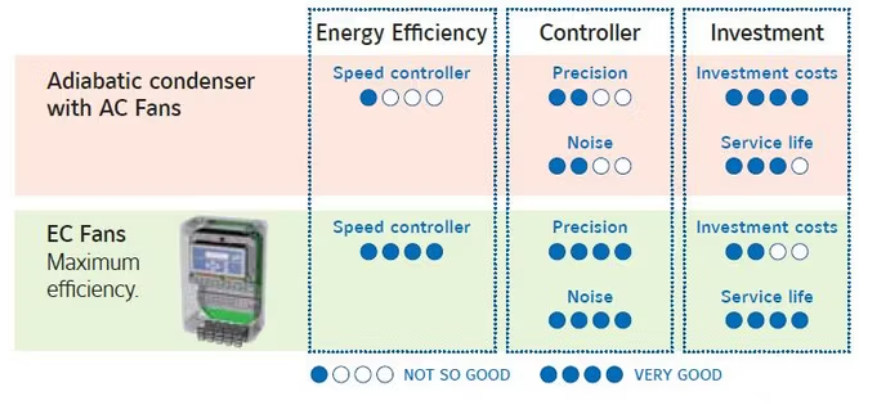

Intelligent Control of Fan Speed and Wetting

1) Water conserved by the volume control

2) Very low energy consumption using Electronically Commutated (EC) motors/fans

3) Very low water consumption with a high dry operation switching

Optimal Adiabatic Cooling Delivery System

1)Maximum adiabatic efficiency

2)Plume-free

3)No water circulation

4)System checked for aerosol output

5)Automatic draining

6)Dry cooling coil

7)No spraying

8)No water treatment required in most cases

Multifunctional Use of Humidification Pads

1) Easily removable for additional dry operation capacity

2)Reliable adiabatic-cooling delivery system

3)Protects coil from dirt and debris

Integrated, Intelligent Control

1)Wired ready to use

2)EC motors with a built-in fan speed controller

3)Motor Management step controller for fan cycling

Installation

1)Easily rigged by crane thanks to easily accessible lifting lugs

2)Quick and easy installation

3)Optimal distribution of forces

4)Rigid structure, resistant to deflection

Company Profile

Shandong Casen Heat Transfer Technology CO,.Ltd

Over the past decade, CASEN has rapidly developed in industrial evaporative and air-cooled cooling, committed to delivering high-quality, customized solutions. Our passionate, professional, and efficient team has earned strong customer trust and recognition.

CASEN upholds a culture of integrity, loyalty, and customer-first values. We believe customer satisfaction ensures sustainable growth, and we never take trust for granted. Innovation and environmental responsibility are at the heart of our development—driving energy-saving technologies and reducing carbon emissions.

With over 1,000 cases across industries, CASEN offers intelligent, energy-efficient solutions tailored to customer needs. We aim to make your work easier and the world greener, consistently delivering reliable, forward-thinking services. Thank you for your continued trust and inspiration.