Product Details

Customization: Available

Cooling Method: Cross Flow

Ventilation Mode: Mechanical Ventilation

Product Description

Model NO. | Cooling tower fill | Material | PVC/PE |

Air Contact Form | Wet | Air Contact Way | Open |

Tower Shape | Round | Noise Level | Ordinary |

Application Fields | Industrial | Certification | ISO, CE, SGS |

Condition | New | Transport Package | Container |

Specification | Custom | Trademark | CASEN |

Origin | China | HS Code | 84199090 |

Production Capacity | 100tons/Month |

|

Product Description

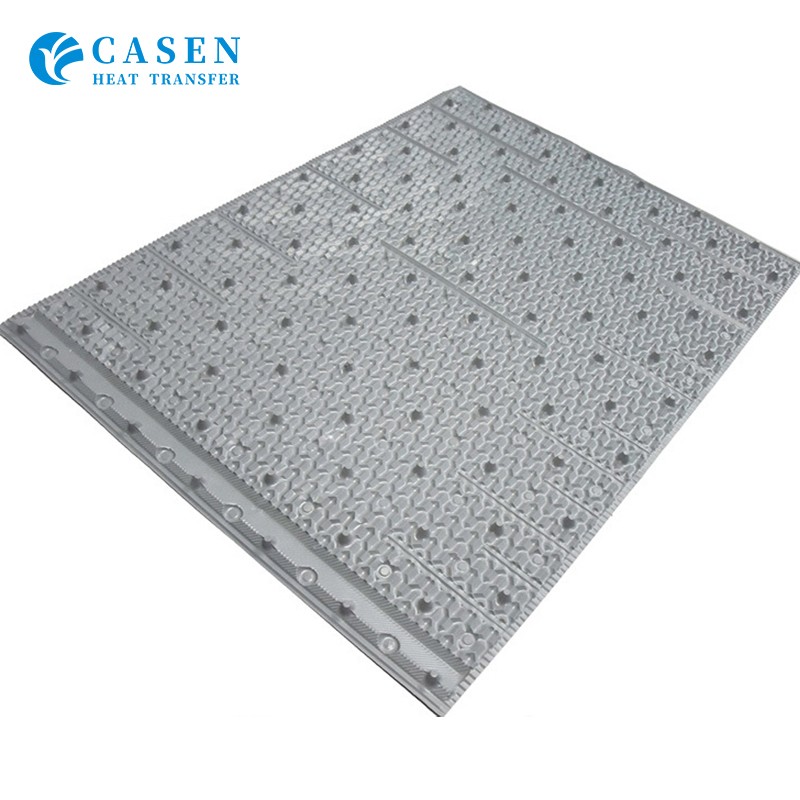

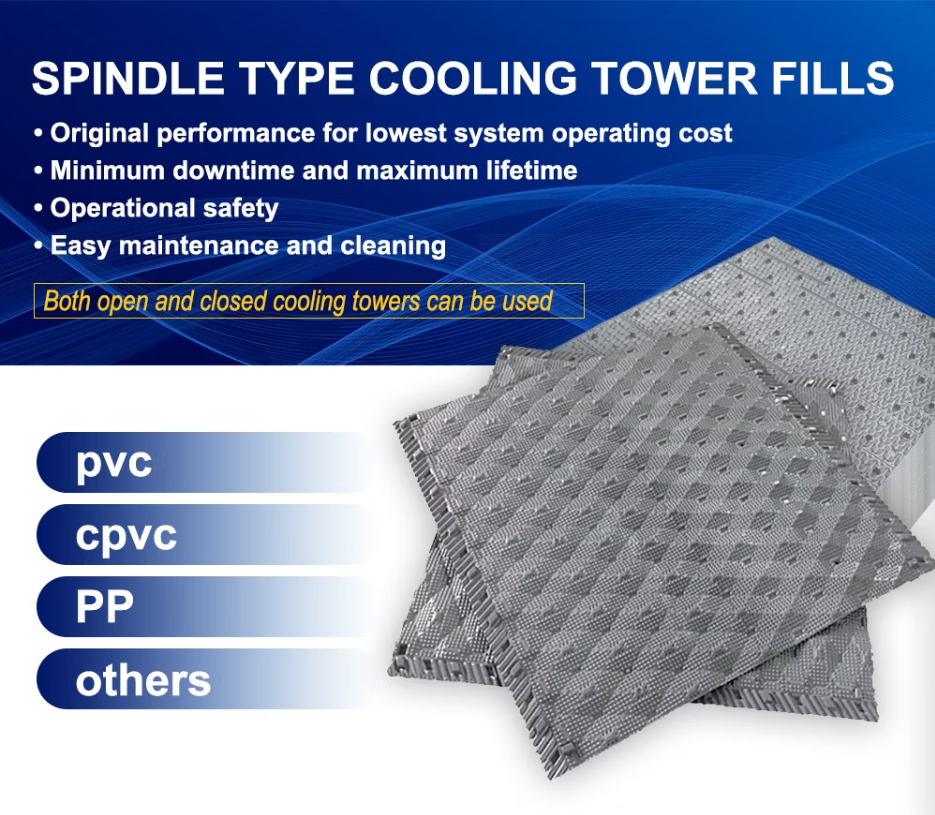

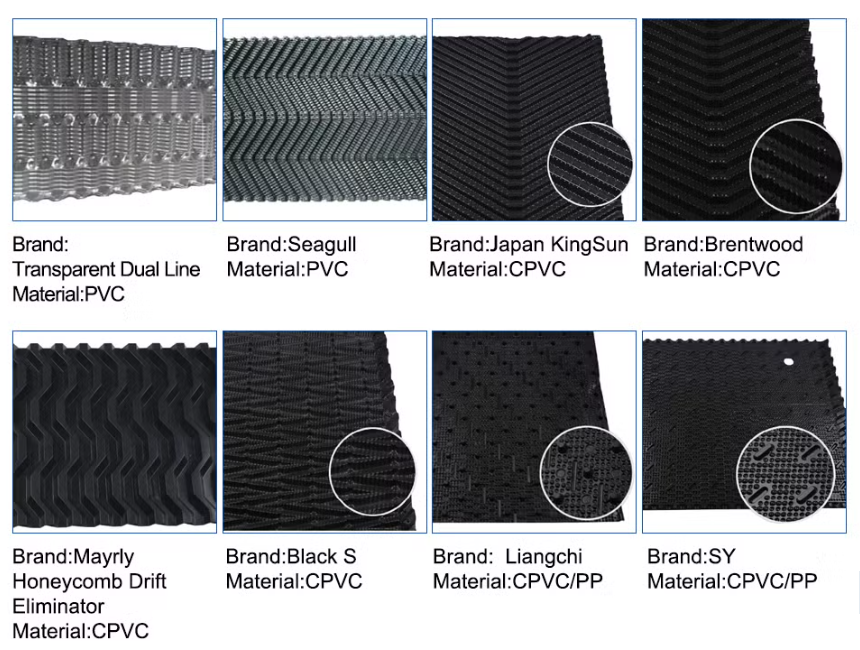

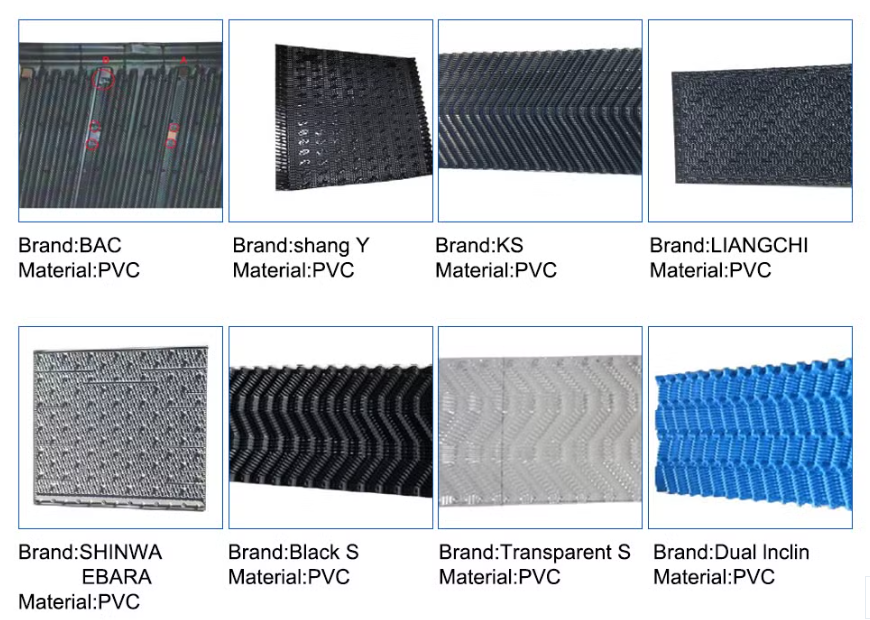

PVC Cooling Tower Fills

Many modern cooling towers utilize efficient plastic film fills that maximizes surface area for evaporative cooling. Water is distributed onto the fill and spreads into a thin film, increasing the air-water interface and allowing waste heat to evaporate at an accelerated rate. The main factors driving fill selection are Total Suspended Solids (T SS) levels, water make-up, intended treatment, and potential for contamination.

Technical Parameters

Size(mm) | Width(mm) | Height(mm) | Thickness(mm) | Wave depth(mm) |

850*1000 | 850 | 1000 | 0.3 | 14.5 |

1000*1000 | 1000 | 1000 | 0.3 | 14.5 |

OEM | We can produce as your request | |||

• Brand: SPINDLE

• Size:850 x 1000 mm

1300 x 1000 mm

• Thickness: 0.28-0.33 mm

• Flute: 16 mm

• Material: PVC.

• Fire Classification: M2.

• Typical Sheet Size: As requested.

• Color: Black, blue, transparent, or other

• Working Temperature: 65 °C.

• With 42% Oxygen Index.

Feature

• Film fills to fit any application, and water quality level.

• Widest range of flute geometries to control fouling.

• High thermal performance options.

• New tower construction as well as retrofit applications.

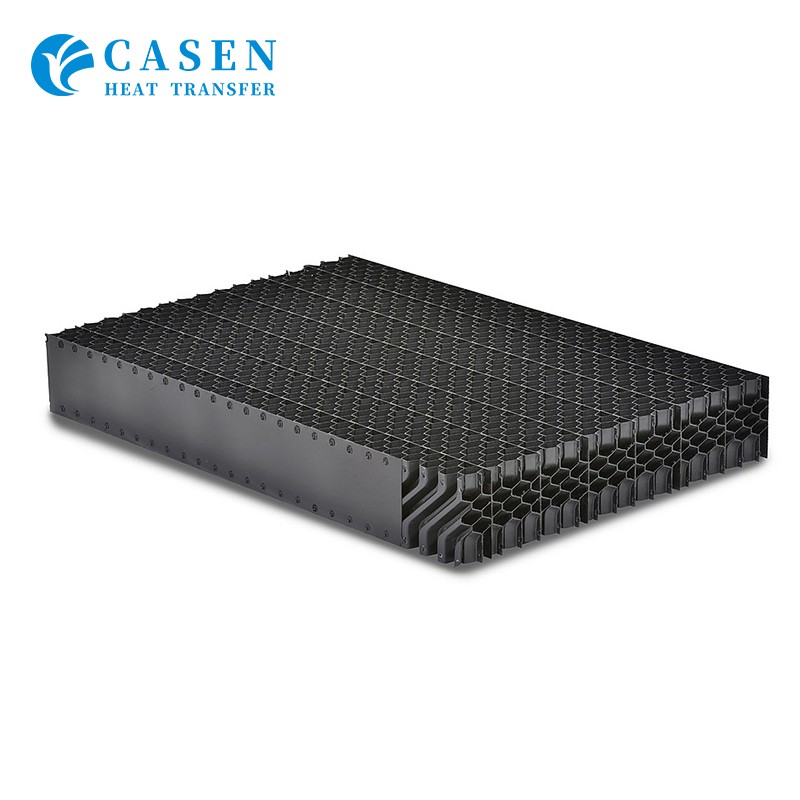

CPVC Cooling Tower Fills

CPVC cooling tower fill is an advanced product of PVC fills. The main materials of CPVC fills are chlorine and polyvinyl chloride. It has excellent high-temperature resistance, chemical resistance, high mechanical strength and fire resistance performance.

Technical Parameters

• Material: CPVC, polycarbonate, ABS, or other.

• Material Grade: Flame spread rate not to exceed 25 per ASTM E-84

• Working Temperature: 75°C to 85°C.

• Tensile Strength: 6300 PSI.

• Typical Sheet Size: As request

• Color: Black, blue, transparent, or other customized colors

• With 42% Oxygen Index.

Feature

• Extremely high-temperature resistance.

Compared with PVC fills and PP fills. The maximum working temperature of PVC fills is 65°C and PP is 90°C. The maximum working temperature of C can achieve 100°C. It can supply maximum pressure loading capacity but also supplies the longest service life in the high-temperature environments

• Corrosion resistance.

The high content of chlorine element supplies excellent chemical sta buy, it can resist acid, alkali, salty and another organic solvent

• Fire resistance performance.

Fire resistance is the most outstanding performance of CPVC cooling tower fills. It can neither be self-burning nor contribute to burning. The LOI (Limiting Oxygen Index) can achieve 46, which is the highest grade of fire resistance.

RELATED PARTS

Shandong Casen Heat Transfer Technology CO,.Ltd

Over the past decade, CASEN has rapidly developed in industrial evaporative and air-cooled cooling, committed to delivering high-quality, customized solutions. Our passionate, professional, and efficient team has earned strong customer trust and recognition.

CASEN upholds a culture of integrity, loyalty, and customer-first values. We believe customer satisfaction ensures sustainable growth, and we never take trust for granted. Innovation and environmental responsibility are at the heart of our development—driving energy-saving technologies and reducing carbon emissions.

With over 1,000 cases across industries, CASEN offers intelligent, energy-efficient solutions tailored to customer needs. We aim to make your work easier and the world greener, consistently delivering reliable, forward-thinking services. Thank you for your continued trust and inspiration.