1. Necessity of cooling injection molding machines

Injection molding machines generate a lot of heat during production. If they are not cooled in time, it will lead to:

-Deterioration of product quality (deformation or surface defects).

-Shortening of equipment life (high temperature accelerates aging).

-Increased energy consumption (low cooling efficiency prolongs production cycle).

An efficient cooling system is the key to stable operation of injection molding machines and product quality.

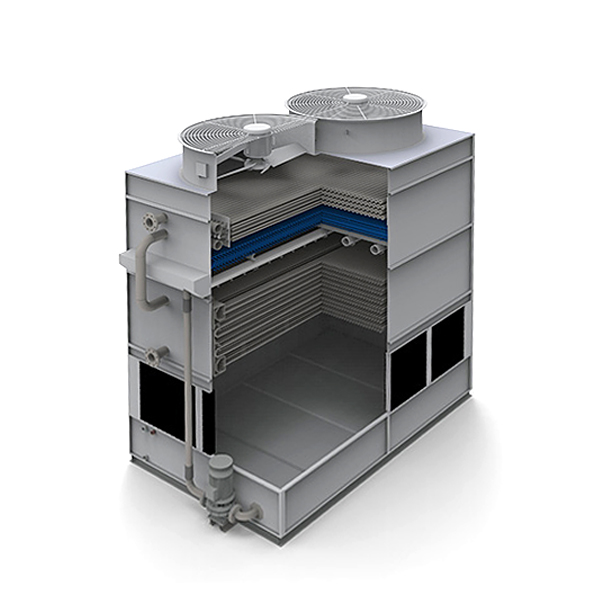

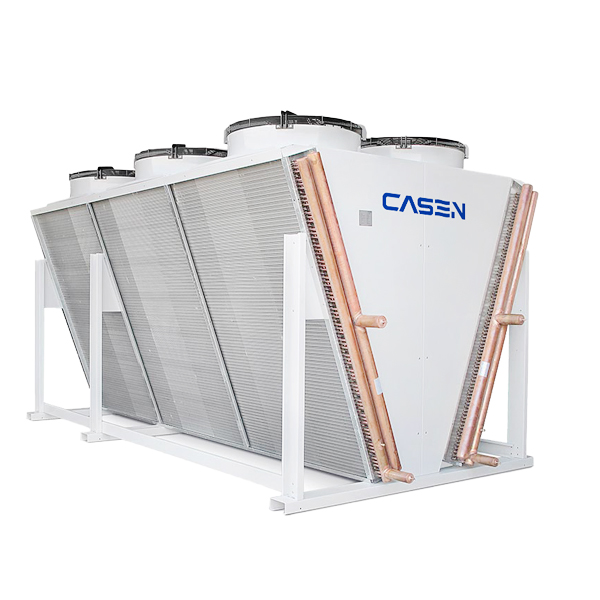

2. Advantages of CASEN open cooling towers

(1) Efficient cooling

Efficient filler and spray system, cooling efficiency increased by 20%.

(2) Energy saving and consumption reduction

Energy saving of 15%-25% compared to traditional equipment, intelligent control system further reduces energy consumption.

(3) Low cost maintenance

Simple structure, easy maintenance, corrosion-resistant materials extend service life.

(4) Strong adaptability

Adapt to high temperature and high humidity environment, modular design supports expansion.

(5) Environmental protection and water saving

The circulating water system reduces water consumption, and is equipped with water treatment equipment to ensure water quality.

3. Summary

CASEN open cooling tower solves the problems of low cooling efficiency and high energy consumption of injection molding machines, improves production efficiency and product quality, demonstrates its technical strength in the field of industrial cooling, and lays the foundation for the promotion of manufacturing industry.