Background & Challenge

CASEN designed and installed a closed circuit (closed loop) cooling tower for a factory in an industrial park in Oman. The site faces high ambient temperatures, salt-laden air and hard water — conditions that make open cooling systems prone to scaling, corrosion and heavy makeup-water demand. The customer required a fast, low-maintenance solution that would not disrupt production.

Solution Highlights

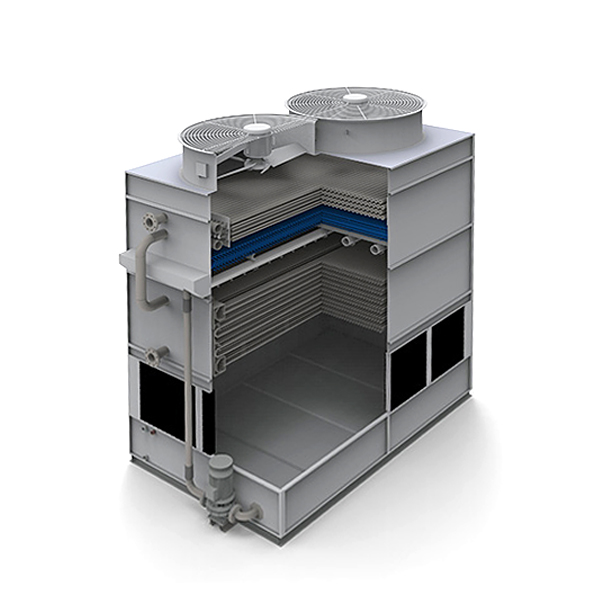

Closed-circuit design with sealed coil heat exchangers so process fluid never contacts ambient air, greatly reducing scaling and corrosion.

Corrosion-resistant materials and protective coatings at critical points.

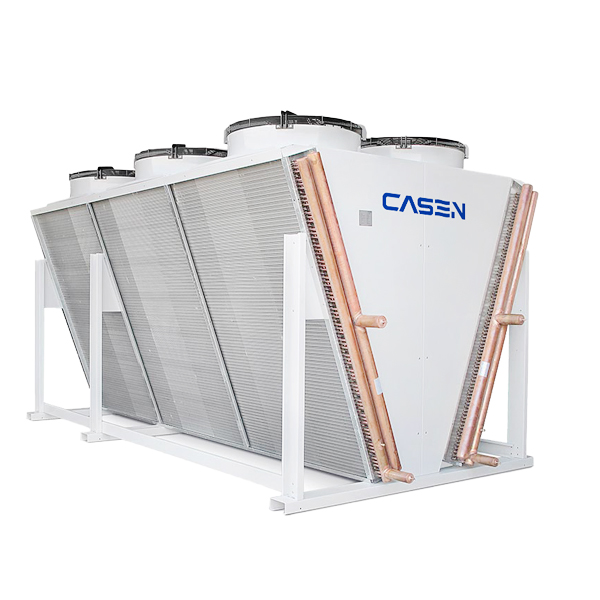

Modular, pre-assembled units to minimize on-site installation time and shorten production downtime.

Optimized water-treatment and control logic to maintain stable temperatures under peak heat loads.

Implementation Snapshot

After a focused site survey, CASEN shipped pre-assembled modules and performed nighttime pipe switchover during a production lull. Commissioning included control fine-tuning; the system reached stable, load-bearing operation on the first full test — prompting positive response from the client’s operations team.

Performance & Client Feedback

Stable continuous operation with no heat-exchange related shutdowns.

Marked reduction in maintenance effort and cleaning frequency.

Lower makeup-water and chemical treatment costs.

Client reported performance “exceeding expectations” and recommended CASEN to other regional sites.

Conclusion

In harsh coastal/desert environments, a closed circuit cooling tower — combined with proper material selection and modular execution — delivers reliable cooling, significant water savings and lower lifecycle maintenance, making it a strong choice for industrial users with high reliability and low-maintenance requirements.