[Company News | July 2025]

We are pleased to announce the successful completion and upcoming shipment of a Cross Flow closed circuit cooling tower equipped with a comprehensive auxiliary system. The unit is now en route to the construction site of a large-scale high-end data center project in Dubai, UAE, marking a significant step forward in our company's expansion into the Middle East high-temperature cooling market.

This bespoke cooling system was developed in response to the client's rigorous requirements for the rmal stability, energy efficiency, automation, and long-term operational reliability—especially under the extreme climate conditions of the region. The client, a leading digital infrastructure provider in the Gulf region, entrusted our engineering team to deliver a tailored, high-performance cooling solution.

Key Features of the System:

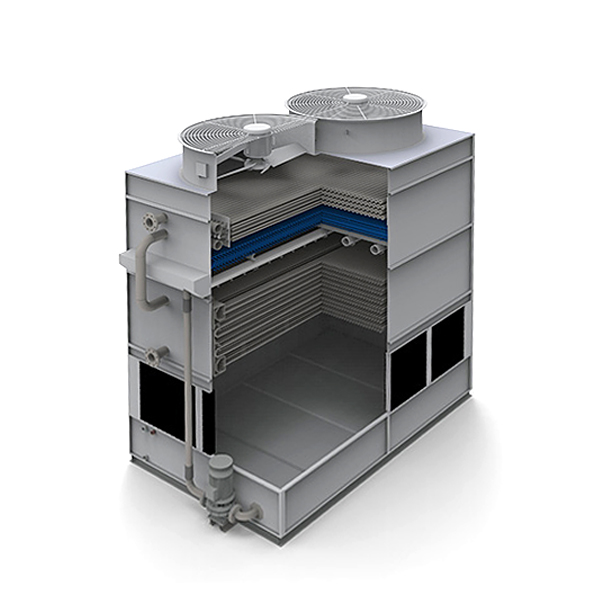

Compact, Efficient Cross Flow Design:

Compared to conventional crossflow or induced draft units, the CrossFlow configuration offers more compact footprint, optimized airflow, and higher heat exchange efficiency—making it ideal for high-density environments such as data centers and chip manufacturing facilities.

Integrated Auxiliary Systems:

The tower comes equipped with a full set of auxiliary units, including automatic chemical dosing, electronic water treatment, softener units, and real-time monitoring modules. These ensure excellent water quality inside the system, minimize scaling and fouling, and extend the life of all internal components.

Smart Control Architecture:

The unit features our proprietary PLC-based intelligent control logic, offering automation of fan and pump operation, pressure modulation, temperature curve adjustment, and fault alerts. It also supports both Modbus and BACnet communication protocols for seamless BMS integration.

Energy and Water Savings Certified:

According to third-party testing, this system reduces energy consumption by 18–22% and cuts water usage by around 15% compared to traditional cooling methods—making it a true low-carbon cooling alternative.

This project is another successful example of our "Customization + Modularization" strategy. Despite the tight schedule, our team managed to complete design, production, and commissioning in just 45 days through meticulous project management and precise engineering workflows—earning high praise from the client.

“Your team not only understood our needs, but delivered a high-performance solution with incredible responsiveness. This level of service gives us great confidence in the on-time commissioning of our project.”

— Technical Director, Client Side

Once operational, the cooling tower will serve as the central thermal control backbone of the data center, operating more than 20 hours per day year-round. The facility is projected to handle over 12 petabytes of data daily, making cooling performance and stability absolutely critical.

We continue to uphold our development philosophy of scenario-driven engineering and innovation-led design, pushing forward in sectors like data centers, smart manufacturing, and high-end industrial cooling. Our goal remains constant: to provide intelligent, sustainable, and reliable cooling technologies to clients around the world.