Client industry: Specialty chemicals (name withheld)

Location: Industrial park, Foshan area, Guangdong Province, Southern China

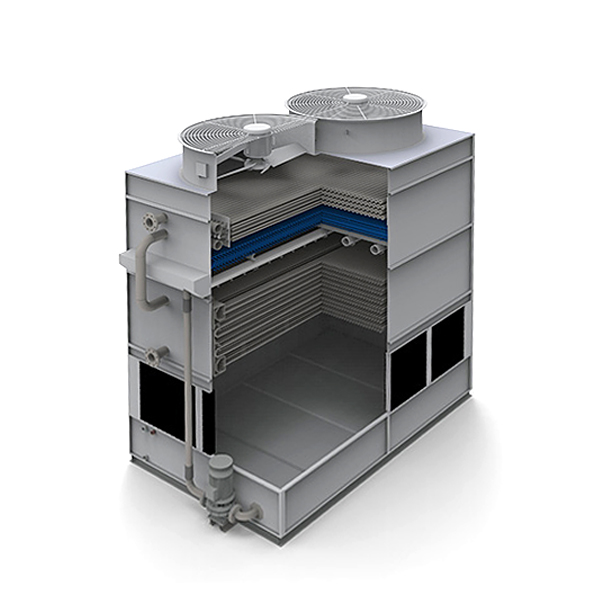

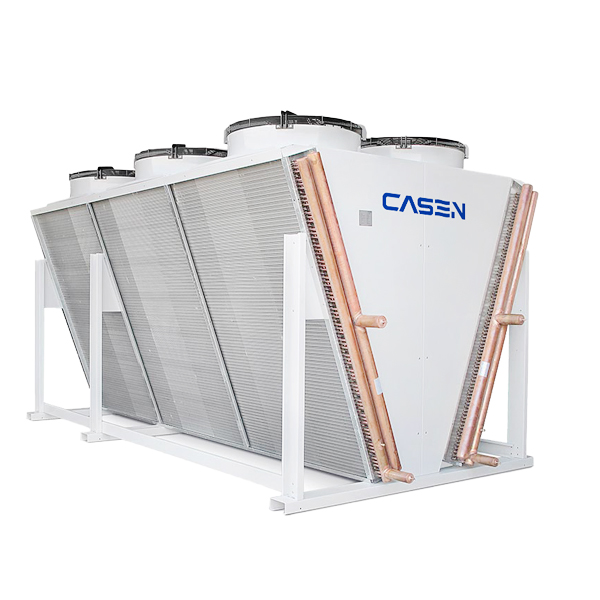

Equipment: Custom crossflow closed-circuit cooling tower — three-fan configuration, modular skid design

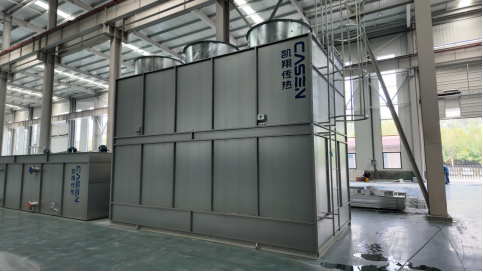

Status: Production & FAT complete — packed and ready for road delivery

Project snapshot

A specialty chemical plant experienced temperature control issues during scale-up: high summer wet-bulb conditions and limited yard space rendered the legacy cooler inadequate. Casen supplied a purpose-built crossflow closed-circuit cooling tower sized to the site heat-load and climate.

Key custom features

Three high-efficiency fans + VFDs for matched airflow, soft start and part-load energy savings.

Enlarged coil area & multi-circuit banks to meet peak summer duty while keeping pump loads acceptable.

Corrosion-resistant construction (hot-dip galvanizing, selective stainless steel, epoxy coating).

Modular packaging & on-site assembly kit for road-transport limits and fast erection.

PLC + BMS interface for remote monitoring.

Factory Acceptance Testing (FAT): full thermal, vibration and electrical checks passed.

Expected outcomes

Maintain process outlet temperature within ±1.5 °C under peak conditions.

Estimated energy savings at part load due to VFD control (site dependent).

Reduced maintenance time thanks to modular fan banks and improved access.

Next steps

Road transport → on-site reassembly → electrical & BMS integration → 72-hour trial run → formal handover with O&M manual and FAT report.