Client Industry: New Energy Lithium Battery Cathode Material

Project Location: Fuzhou Industrial Zone, Fujian Province, China

Application Scenario: High-Precision Production Process Cooling

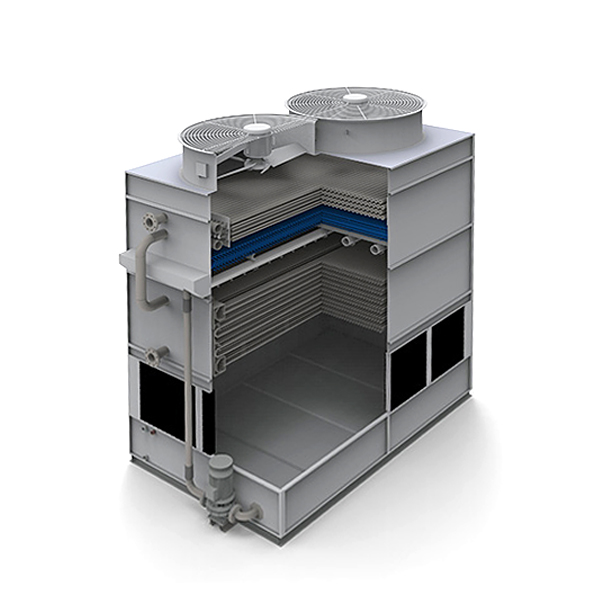

Solution: Counterflow Closed Cooling Tower (Customized Three-Fan Configuration)

Client Challenges

As a globally leading supplier of lithium battery materials, this client faced extremely stringent requirements for the temperature control system serving key reaction kettles in its newly built digital factory. The original cooling solution encountered the following core challenges:

l High Temperature Sensitivity: Chemical reactions are highly sensitive to fluctuations in inlet water temperature, requiring control within a narrow range of ±1.0°C.

l Significant Energy Efficiency Targets: As a benchmark green factory project, there are strict regulations regarding the energy consumption and water-saving indicators of production support equipment.

l Compact Spatial Layout: Limited installation space on the plant roof required equipment that is lightweight and has a compact structure.

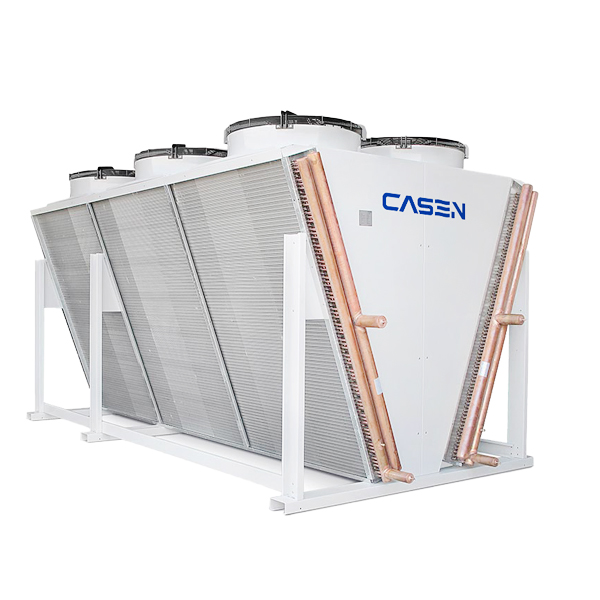

Casen Heat Transfer Customized Solution

l Precise Temperature Control & Water Quality Assurance: The fully enclosed circulation design prevents cooling water from contacting the outside air, fundamentally avoiding contamination and evaporation loss. This ensures high cleanliness of the process cooling water and stable outlet temperature, perfectly meeting production process requirements.

Outstanding Energy and Water Saving Performance

l Energy Saving: Equipped with high-efficiency permanent magnet synchronous motors and an intelligent variable frequency control system, it automatically adjusts fan speed based on ambient wet-bulb temperature and load changes. It utilizes natural cooling sources during transitional seasons and winter for efficient heat exchange, achieving a comprehensive energy saving rate of over 25% compared to traditional solutions.

l Water Saving: Compared to traditional open cooling towers, the fully closed circuit avoids water drift and evaporation loss, with a water saving rate exceeding 95%, significantly reducing the client's water costs and wastewater treatment burden.

l Compact Structural Design: The optimized coil and casing structure maximize heat exchange capacity per unit area, meeting the client's installation requirements within limited roof space.

Project Value

Once operational, this cooling system will create significant value for the client:

l Ensures Core Production: Provides a stable and reliable temperature environment for the production of high-quality lithium battery materials, ensuring product consistency from the source.

l Reduces Operating Costs: Significant energy and water savings directly lower the factory's daily operating costs, resulting in a short investment payback period.

l Builds a Green Factory: Extremely low water consumption and energy consumption strongly support the client's strategic goal of building a national-level green factory, enhancing the company's environmental image.

Leveraging profound technical expertise and extensive project experience, Casen Heat Transfer has once again provided reliable industrial cooling support for the critical new energy materials sector, earning the client's trust.