-Factory Background

A large chemical plant in Thailand specializes in producing chemical raw materials and fine chemical products, with an annual production capacity exceeding one million tons. Located in the Eastern Industrial Zone of Thailand, the plant operates in a hot and humid climate year-round. The limited efficiency of traditional cooling systems, rising water costs, and increasingly strict environmental regulations have created an urgent need for a high-efficiency, water-saving, and environmentally friendly cooling solution to optimize production operations.

-Project Overview

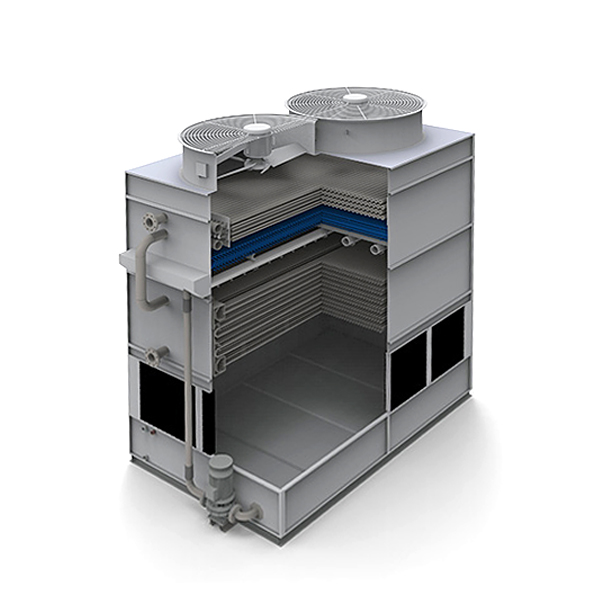

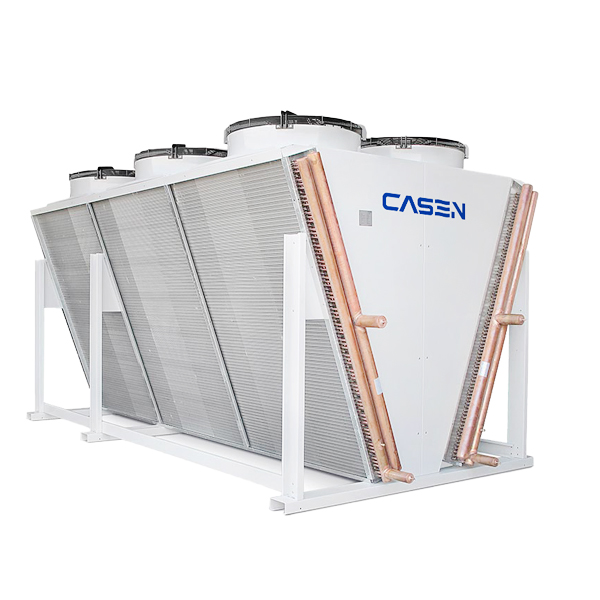

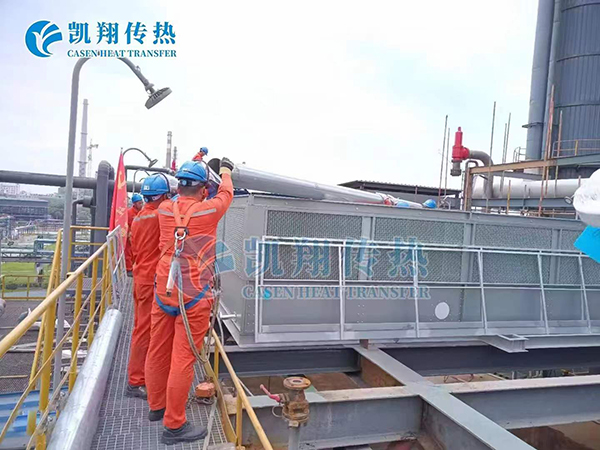

After extensive technical comparisons, the chemical plant selected the CASEN closed circuit cooling tower as its core cooling equipment. This project involved upgrading the cooling systems of multiple production lines. The CASEN team provided a customized cooling solution, ensuring stable cooling performance even in high-temperature environments. The project was successfully installed and commissioned within just two months.

-Key Advantages

1.High Efficiency & Stability

2.Water-Saving & Eco-Friendly

3.Low Maintenance Costs

4.Corrosion Resistance

5.Energy Efficiency & Cost Reduction

-Summary

The successful application of CASEN closed circuit cooling towers in this Thai chemical plant has not only significantly improved cooling efficiency but also reduced water consumption and maintenance costs, providing greater economic value for the enterprise. This case highlights CASEN’s technological leadership in industrial cooling solutions for high-temperature, high-humidity environments and strengthens its presence in the Thai and Southeast Asian markets. Moving forward, CASEN remains committed to delivering efficient, eco-friendly, and energy-saving cooling solutions to global customers.