Product Description

Product Introduction of open cooling tower

Open cooling systems incorporate a pond or cooling tower for heat removal. Warm water picked up from the process via heat exchangers is returned to the pond or tower and heat is removed through evaporation of a portion of the cooling water.

Open cooling towers are indispensable equipment in modern industry. They are applied in almost all scenarios that require safe and efficient elevated work, such as construction, industry and manufacturing, power and energy, etc.

Design Structure And Features

Solid structure

The overall structure is solid and lightweight, with the shell and water collection basin made of reinforced glass fiber (FRP fiberglass). It is corrosion-resistant. The surface coating contains ultraviolet inhibitors, making it durable.

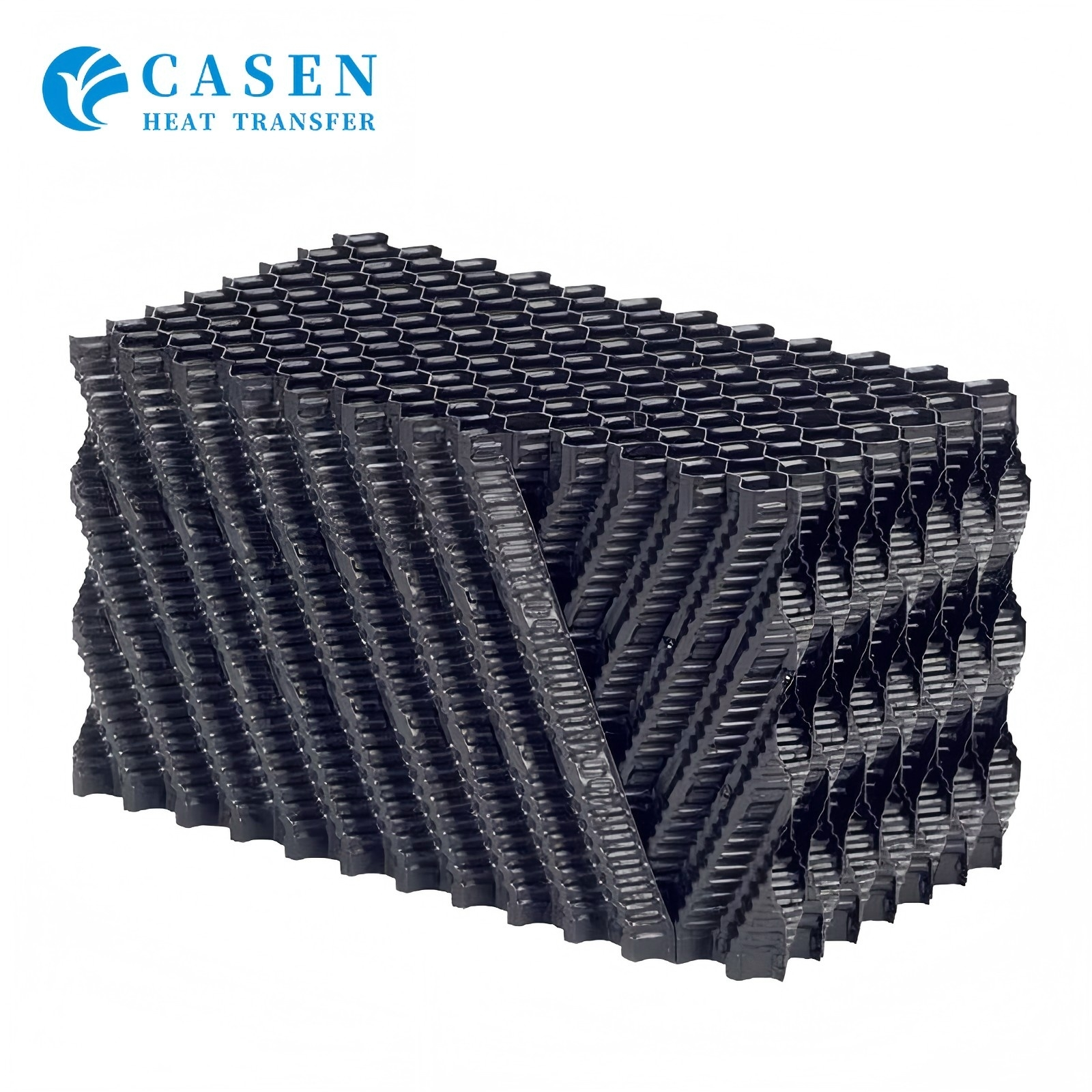

PVC material

The axial-flow fan is made of PVC material, featuring ample air volume, low noise, low rotational speed and low energy consumption. The heat dissipation is achieved through honeycomb-shaped vacuum-molded PVC or PP fillers.

Characteristics

1.Low Noise

PVC fills make high work efficiency and also can reduce the noisy of spray drops. Configure low noisefans.

2.Avoiding scaling

The spray water's temperature is lower than scaling temperature, smooth flow the cooling coil andthe coils are damped completely, highly reduce scaling.

3.Convenient Maintenance

Modular design is easy to assemble, disassemble and maintenance.There is a maintenance passageinside the tower.lt can be repaired and cleaned without stopping the machine.There aremaintenance ladder and fence,which are convenient for staff to examine and repair.

Product Details

| Customization: | Available |

| After-sales Service: | Available |

| Warranty: | 18 Month |

Shipping

| Shipping Cost | Contact the supplier about freight and estimated delivery time. |

ShippingBasic Info

| Model NO.: | Casen |

| Cooling Method: | Counter Flow |

| Ventilation Mode: | Mechanical Ventilation |

| Casing Material: | FRP |

| Air Contact Form: | Wet |

| Air Contact Way: | Open |

| Tower Shape: | Circular/square shape |

| Noise Level: | Low |

| Certification: | ISO, CE, SGS |

| Condition: | New |

| Products: | Types Cooling Tower |

| Type: | Counter Flow Type |

| Casing Material: | CaFRP |

| Fan: | FRP Blades |

| Fill: | PVC Fills |

| Fill Type: | Counter Flow Type |

| Nozzels: | ABS |

| Frame Structure: | Ss, HDG Steel |

| Specification: | 15RT-335RT |

| Origin: | China |

| HS Code: | 8418699090 |

| Production Capacity: | 200sets/Month |

Packaging & Delivery

| Package Size: | 1000.00cm * 1000.00cm * 1000.00cm |

| Package Gross Weight: | 3000.000kg |

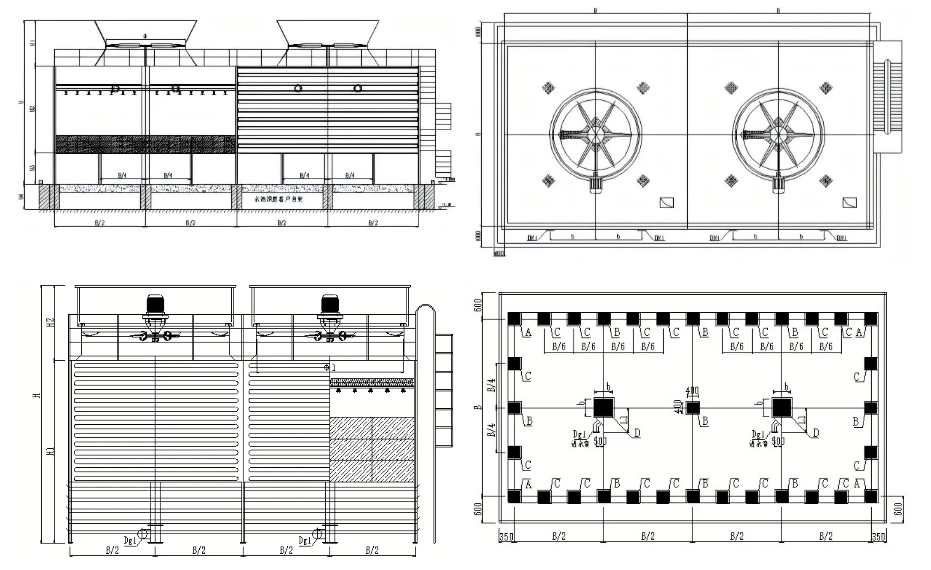

Partial schematic diagram of open cooling tower

Specification

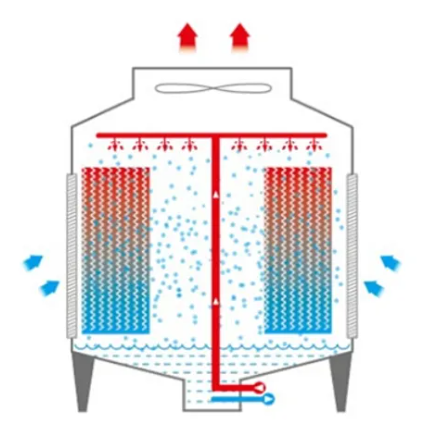

Principle of Operation

In the cross-flow cooling water tower, the water falls from the top, the flow of air and the flow of water flow into a vertical flow, due to the relationship between the transverse air intake, so the distance between the part of the cooling material and the bottom water tray is very close, reducing t4000he noise of the water falling.

Model | Dimension | Fan | |||||

W | L | H | Dia | Motor | Volume | Number of blades | |

mm | mm | mm | Φmm | KW | m³/h | ||

KKH-100 | 3500 | 2000 | 3455 | 1600 | 3 | 43400 | 4 |

KKH-125 | 3700 | 2100 | 3455 | 1800 | 4 | 62000 | 4 |

KKH-150 | 3900 | 2650 | 3455 | 2000 | 5.5 | 92000 | 4 |

KKH-250 | 4700 | 3250 | 4550 | 2800 | 7.5 | 150000 | 6 |

KKH-300 | 5100 | 3650 | 4650 | 3200 | 11 | 180000 | 6 |

KKH-350 | 5100 | 3800 | 4650 | 3200 | 11 | 187500 | 6 |

KKH-600 | 6100 | 4900 | 4700 | 3800 | 22 | 265000 | 6 |

KKH-700 | 6300 | 5200 | 4700 | 4000 | 22 | 330000 | 6 |

KKH-800 | 7500 | 5500 | 5200 | 4000 | 30 | 360000 | 6 |

Packing & Delivery

Company Profile

Shandong Casen Heat Transfer Technology CO,.Ltd

Over the past decade, CASEN has rapidly developed in industrial evaporative and air-cooled cooling, committed to delivering high-quality, customized solutions. Our passionate, professional, and efficient team has earned strong customer trust and recognition.

CASEN upholds a culture of integrity, loyalty, and customer-first values. We believe customer satisfaction ensures sustainable growth, and we never take trust for granted. Innovation and environmental responsibility are at the heart of our development—driving energy-saving technologies and reducing carbon emissions.

With over 1,000 cases across industries, CASEN offers intelligent, energy-efficient solutions tailored to customer needs. We aim to make your work easier and the world greener, consistently delivering reliable, forward-thinking services. Thank you for your continued trust and inspiration.